Are you struggling to select the right interior panels for your vessel? The harsh marine environment demands materials that are not only aesthetically pleasing but also incredibly durable and compliant with strict safety standards.

A marine wall panel is a specialized non-combustible panel used for constructing interior walls, ceilings, and bulkheads within ships and offshore platforms. These panels are engineered to be lightweight, fire-resistant, and resistant to moisture, providing structural integrity, insulation, and a finished decorative surface.

Choosing the wrong panel can lead to costly repairs, safety hazards, and non-compliance with maritime regulations. As a marine interior outfitting specialist, I've seen firsthand how crucial the right wall panels are for the safety, comfort, and longevity of a vessel. In this post, I'll guide you through everything you need to know about marine wall panels, drawing from my years of experience at Magellan Marine and my early days in a marine interior factory.

What are the primary functions of a marine wall panel?

Are you wondering what makes marine wall panels so essential? Beyond just dividing a space, these panels are multi-functional components critical to a vessel's safety and habitability, a fact I quickly learned in my career.

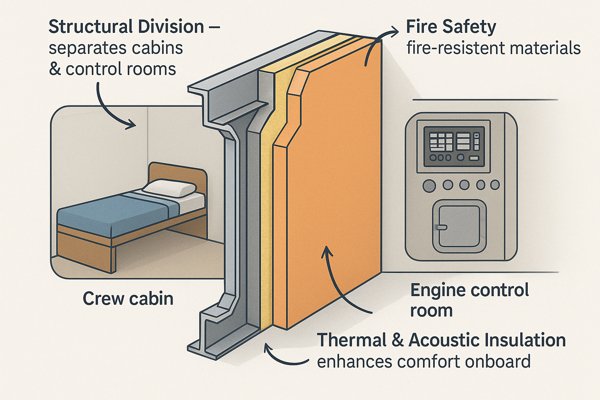

Marine wall panels serve three primary functions: providing structural division, ensuring fire safety, and offering thermal and acoustic insulation. They create separate compartments, from crew cabins to engine control rooms, while meeting stringent fire-resistance standards and enhancing comfort for everyone on board.

When I first started, I thought a wall was just a wall. But on a ship, it's a critical safety system. The main job of these panels is to form fire-rated divisions, known as bulkheads and decks. They are not just walls; they are engineered barriers designed to perform under extreme conditions. The table below summarizes these core functions.

| Function | Primary Purpose | Key Benefit |

|---|---|---|

| Fire Safety | To contain fire and smoke within a specific compartment. | Prevents fire spread, protects escape routes, allows time for firefighting. |

| Insulation | To block the transfer of heat and sound. | Improves energy efficiency (lower HVAC costs), enhances crew comfort and rest. |

| Space Division | To create the functional layout of the vessel's interior. | Defines cabins, corridors, and public spaces, making the vessel habitable. |

Function 1: Fire Containment and Passive Safety

The number one function is to create fire-rated compartments. According to the International Convention for the Safety of Life at Sea (SOLAS), ships must be divided into Main Vertical Zones by thermal and structural boundaries. The goal is to contain a fire in the compartment where it starts, preventing its spread and allowing time for firefighting and evacuation. A marine wall panel system is designed and tested as a whole—panels, profiles, and doors—to withstand the intense heat of a standard fire curve for a specific period. This compartmentalization is the foundation of a ship's passive fire protection strategy, acting as a fixed, always-on safety measure.

Function 2: Structural Contribution and Space Division

While interior wall panels are not primary structural elements like the ship's hull or main transverse bulkheads (meaning they are not designed to bear the ship's load), they do contribute to the overall stiffness of the accommodation block. More importantly, they provide the functional division of space that makes a vessel habitable. They create the layout of cabins, corridors, offices, hospitals, and public areas. This must be done with precision, as the placement of every wall is defined in the ship's General Arrangement plan and must adhere to regulations regarding escape route widths and cabin sizes.

Function 3: Thermal Insulation and Energy Efficiency

Ships operate in every climate imaginable, from the freezing Arctic to the sweltering tropics. Maintaining a stable and comfortable temperature inside the accommodation areas is crucial for crew well-being and operational effectiveness. The core materials of these panels, like rock wool, have excellent thermal insulation properties. For instance, a standard 50mm rock wool panel can have a thermal transmittance value (U-value) as low as 0.7 W/m²K. This barrier to heat transfer significantly reduces the load on the ship's HVAC (Heating, Ventilation, and Air Conditioning) systems. I once worked on a vessel refit where upgrading the interior panels resulted in a documented 15% reduction in HVAC energy consumption, a huge operational saving over the vessel's life.

Function 4: Acoustic Insulation for Crew Comfort

A ship is an incredibly noisy environment. The constant low-frequency drone of engines, generators, and other machinery can lead to crew fatigue and communication issues. Marine wall panels provide crucial acoustic insulation to create a quieter, more livable space. A standard 50mm thick rock wool panel can achieve a Sound Reduction Index (Rw)1 of around 33 dB. For areas requiring enhanced silence, like hospital bays or the captain's cabin, specialized acoustic panels or double-wall constructions can be used to achieve sound reduction of 50 dB or more. This isn't just a luxury; it's a health and safety requirement under maritime labor conventions to protect the crew's hearing and ensure they get proper rest.

What common materials are used to construct marine wall panels?

Confused by the different types of marine panels available? The choice of material is critical, as it directly impacts the panel's performance, weight, and cost. It's a balance I've helped many clients navigate.

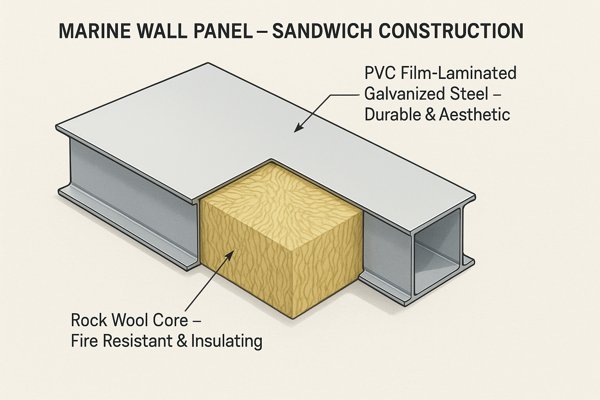

The most common construction for marine wall panels is a sandwich structure, featuring a core material laminated between two surface layers. Core materials include rock wool for fire resistance and insulation, while surface layers are typically PVC film-laminated galvanized steel sheets for durability and aesthetics.

Let's break down the anatomy of the panel to understand how these materials work together.

The Anatomy and Manufacturing of a Sandwich Panel

A sandwich panel is an engineered composite. It consists of two thin, strong outer layers (facings) bonded to a thick, lightweight core. The magic happens in the manufacturing process. Large sheets of galvanized steel are fed through a line where a specialized, fire-retardant polyurethane-based adhesive is applied. The rock wool core is laid on top, followed by another layer of adhesive and the top steel sheet. This "sandwich" then passes through a heated press under high pressure, which cures the adhesive and bonds the layers into a single, incredibly strong and rigid panel. This process is crucial; a failure in the adhesive would compromise the panel's integrity.

Understanding Core Materials: The Heart of the Panel

The core is the heart of the panel and defines its primary properties. The choice of core is a trade-off between performance characteristics, as summarized in the table below.

| Core Material | Key Advantage | Fire Resistance | Thermal Insulation | Acoustic Insulation | Weight |

|---|---|---|---|---|---|

| Rock Wool | Balanced, all-around performer | Excellent | Good | Good | Moderate |

| Aluminum Honeycomb | Ultra-lightweight | Good | Poor | Fair | Very Low |

| Calcium Silicate | Moisture & high fire resistance | Excellent | Good | Fair | High |

| Polyurethane Foam (PUF) | Best thermal insulator | Poor (must be encased) | Excellent | Fair | Very Low |

- Rock Wool: This is the industry workhorse. Made from spun basalt rock fibers, it's non-combustible and can withstand temperatures above 1,000°C. Its density is key; a B-15 panel for a wall might use 120 kg/m³ density rock wool, while a ceiling panel you might walk on could require 150 kg/m³ or higher for added stiffness.

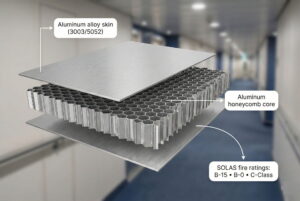

- Aluminum Honeycomb: When weight is the absolute priority, this is the go-to. However, its thermal and acoustic insulation properties are weaker than rock wool. It's often used for C-class partitions on high-speed craft.

- Calcium Silicate: A non-combustible board that is extremely resistant to moisture and dimensionally stable. It's often used as a core or facing in panels for wet units and galleys.

- Emerging Materials: The industry is also seeing new cores, like those made from expanded glass granules, which offer non-combustibility and are even lighter than some rock wool solutions.

Understanding Surface Finishes: The Panel's Protective Skin

The surface provides durability and the final look.

- Galvanized Steel: The standard is a 0.5mm to 0.7mm thick steel sheet with a G60 or G90 zinc coating, indicating the weight of zinc per square foot. A higher number means better corrosion resistance.

- PVC Film Lamination: This is the most common decorative finish, a durable film factory-laminated onto the steel sheet.

- Stainless Steel: For areas requiring the highest level of hygiene and corrosion resistance, like galleys and medical facilities, stainless steel facings (typically 304 or 316 grade) are used. 316 grade has better corrosion resistance and is often specified for offshore platforms.

What makes a wall panel suitable for a marine environment?

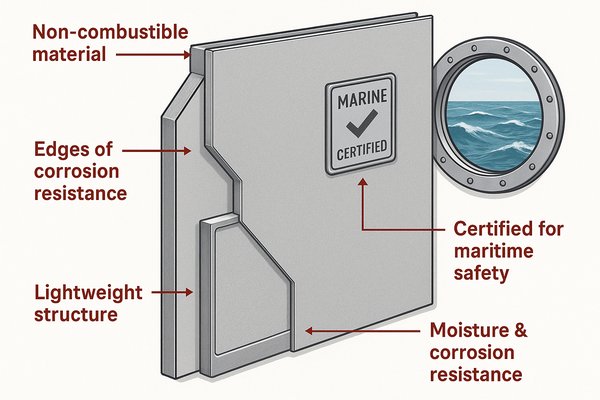

Ever wondered why you can't just use standard drywall on a ship? The marine environment is relentlessly harsh, and any material used must be specifically engineered to withstand its unique challenges.

A wall panel is suitable for a marine environment if it is non-combustible, resistant to moisture and corrosion, lightweight, and certified to meet maritime safety standards. These properties are verified through rigorous testing to ensure longevity, safety, and performance.

Let's break down these critical characteristics and how they are addressed by design and testing.

| Environmental Challenge | Panel Feature / Solution | Verification Method / Test |

|---|---|---|

| Fire Hazard | Non-combustible core (e.g., Rock Wool), steel facings. | IMO FTP Code Fire Test |

| Moisture & Salt | Galvanized steel, sealed PVC film surface, waterproof adhesive. | ASTM B117 Salt Spray Test2 |

| Vibration & Motion | Rigid sandwich construction, flexible profile system. | Laboratory Vibration Test (Shaker Table) |

| Temperature Extremes | Thermally stable materials and adhesives. | Environmental Cycling Test |

Key Trait 1: Certified Fire Safety

This is paramount. Materials must pass the tests outlined in the IMO's FTP Code. This isn't just a one-time test. As part of the Type Approval process (like MED or USCG), manufacturers are subject to ongoing Factory Production Control (FPC) audits. An inspector from a classification society will visit the factory, sometimes unannounced, to ensure the panels being produced today are identical to the ones that were originally fire-tested. They check raw materials, production processes, and quality control records. This ensures consistent safety and quality, which is something I always stress to my procurement clients.

Key Trait 2: Resistance to Moisture and Corrosion

The marine atmosphere is a corrosive cocktail. To prove their resilience, panels undergo specific environmental tests. The ASTM B117 Salt Spray Test, for example, subjects a panel sample to a continuous salt fog for hundreds of hours. Inspectors then look for any sign of rust, blistering, or delamination. This testing proves that the panel's construction, from the galvanization to the adhesive and PVC film, can withstand the harsh reality of life at sea.

Key Trait 3: Durability Against Motion and Vibration

A ship is constantly in motion. Wall systems must withstand these dynamic forces. During type approval, panel systems can be subjected to vibration tests on a shaker table to ensure that the joints won't loosen and the panels won't rattle or fail over years of service. The sandwich construction itself provides excellent rigidity-to-weight, preventing the panels from buckling or warping as the ship's hull flexes in heavy seas.

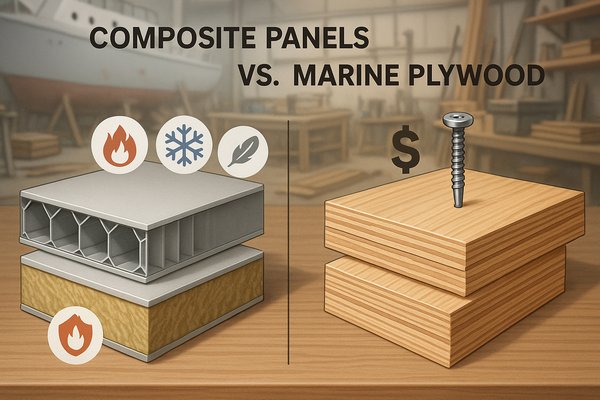

How do composite marine panels compare to traditional marine plywood?

Are you weighing the options between modern composite panels and traditional marine plywood? This is a common dilemma, and the best choice often depends on the specific application, budget, and performance requirements.

Composite marine panels, such as those with rock wool or aluminum honeycomb cores, generally offer superior fire resistance, insulation, and weight savings compared to marine plywood. Plywood, however, can be stronger for holding screws and may have a lower initial material cost.

I've worked with both extensively. Let's do a deep-dive comparison.

Comparing Fire Safety: The Critical Difference

This is the most critical difference. Composite panels with a rock wool core are non-combustible and form the basis of certified A and B-class fire divisions required by SOLAS. Marine plywood, even though it's high quality and made with waterproof glue (like BS 1088 grade), is still a wood product. It is combustible. For any SOLAS-regulated vessel, using plywood for major structural bulkheads in accommodation or service areas is simply not an option.

Comparing Installation Speed and Lifecycle Cost

Here, the modular nature of composite panels provides a huge advantage. They arrive on-site as a complete, pre-finished system. I estimate that using a composite panel system can reduce interior outfitting labor by 30-50% compared to traditional construction. This is a massive saving. Furthermore, consider the lifecycle cost. A properly installed composite panel is virtually maintenance-free. Marine plywood, if its paint or sealant coating is ever breached, can absorb moisture, leading to rot and costly repairs. The lower initial material cost of plywood can be quickly erased by higher labor and future maintenance costs.

Identifying When Plywood is a Suitable Choice

Despite the advantages of composites, marine plywood is still an excellent material for certain applications like furniture, subflooring, and interiors for small craft not subject to SOLAS. Its structural strength and superior screw-holding ability make it the ideal choice for building built-in cabinetry.

| Feature | Composite Marine Panel (Rock Wool) | Marine Plywood (BS 1088) |

|---|---|---|

| Fire Resistance | Excellent (Non-combustible, A & B Class) | Poor (Combustible) |

| Installation | Fast (Modular system) | Slow (Requires framing & finishing) |

| Weight | Lighter overall system | Heavier overall system (with framing) |

| Insulation | Excellent (Thermal & Acoustic) | Moderate (Poor acoustic) |

| Lifecycle Cost | High initial, low maintenance | Low initial, potential high maintenance |

| Best Use | SOLAS-rated bulkheads, walls, ceilings | Furniture, subfloors, non-SOLAS vessels |

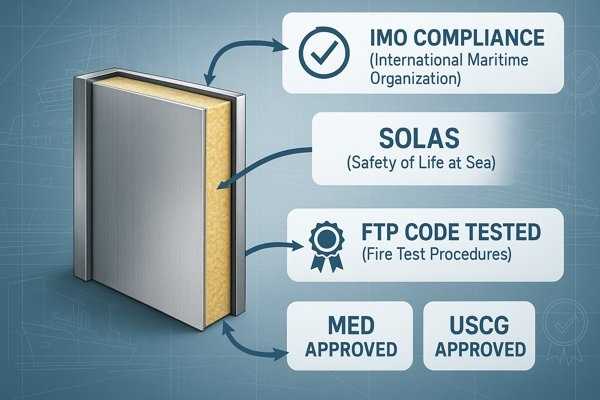

What are the key certifications and standards for marine wall panels?

Feeling overwhelmed by acronyms like IMO, SOLAS, MED, and USCG? Understanding these certifications is non-negotiable, as they are the ultimate guarantee of a panel's safety and quality.

The key certifications for marine wall panels are governed by the International Maritime Organization (IMO). Panels must comply with the Safety of Life at Sea (SOLAS) convention and be tested according to the Fire Test Procedures (FTP) Code, often resulting in MED or USCG approval.

Verifying certifications is the first step in my quality control process. A supplier's claims mean nothing without the proper certificates. Here is a breakdown of the key players.

| Acronym / Name | Type | Role |

|---|---|---|

| IMO | UN Agency | Sets the global standards for maritime safety (The "Rule Maker"). |

| SOLAS | International Treaty | The main convention containing the mandatory safety requirements (The "Rulebook"). |

| FTP Code | IMO Standard | The detailed technical document specifying how to conduct fire tests (The "Test Manual"). |

| MED | EU Directive | Type Approval system for equipment on EU-flagged ships (The "EU Approval Stamp"). |

| USCG | US National Authority | Type Approval system for equipment on US-flagged ships (The "US Approval Stamp"). |

| Class Society (DNV, ABS) | Non-Governmental Org. | Independent third party that verifies standards for insurance/owners (The "Auditor"). |

The Type Approval Process: How Panels Get Certified

A manufacturer can't just claim their product is compliant. They must go through a rigorous "Type Approval" process.

- Application: They apply to a Notified Body (for MED) or the USCG.

- Testing: An independent, accredited fire laboratory builds a sample wall or ceiling system and tests it according to the FTP Code.

- Factory Audit: An inspector audits the manufacturer’s factory to ensure they have a robust quality management system (like ISO 9001) and Factory Production Control (FPC).

- Issuance: If all tests are passed and audits are successful, a Type Approval certificate (e.g., MED-B module) is issued.

- Surveillance: The manufacturer is subject to ongoing annual audits to maintain the certificate. This ensures every panel they produce meets the same standard as the one that was tested.

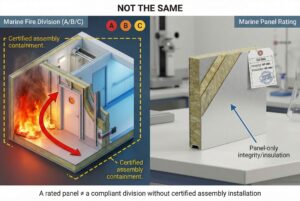

How are marine wall panels classified by fire rating?

Have you seen terms like "A-60" or "B-15" and wondered what they actually mean? This classification is the most critical safety aspect of a marine panel, defining its ability to contain a fire.

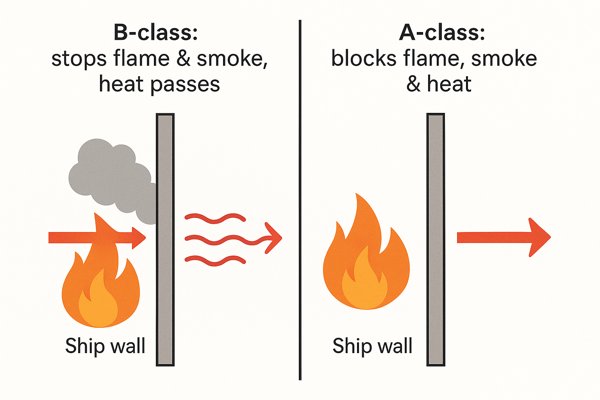

Marine wall panels are classified by fire rating based on their ability to prevent the passage of flame and smoke ('B' class) and to insulate against heat ('A' class) for a specific duration. The number indicates the time in minutes (e.g., 60, 30, 15).

To get a rating, a sample of the wall is exposed to a controlled fire that follows the ISO 834 standard cellulosic fire curve, reaching ~945°C at 60 minutes. Its performance is judged on two criteria: Integrity and Insulation.

| Class | Integrity (Stops Flame) | Insulation (Stops Heat) | Construction Requirement |

|---|---|---|---|

| A | 60 minutes | Time in minutes (0, 15, 30, or 60) | Must be Steel / Equivalent |

| B | 30 minutes | Time in minutes (0 or 15) | Non-combustible materials |

| C | Not Required | Not Required | Non-combustible materials |

Understanding the Standard Fire Test Curve

The ISO 834 standard fire curve3 is meant to simulate the burning of materials in a typical room. The temperature inside the furnace rises rapidly:

- At 5 minutes: ~576°C

- At 30 minutes: ~842°C

- At 60 minutes: ~945°C

A panel that achieves an A-60 rating has withstood these incredibly high temperatures for a full hour without letting the unexposed side get dangerously hot.

Understanding H-Class Ratings for Offshore Applications

For offshore oil and gas platforms, there are even stricter "H" ratings (H-60, H-120). These are tested against a hydrocarbon fire curve, which reaches over 1000°C in just a few minutes, simulating a high-intensity oil or gas fire.

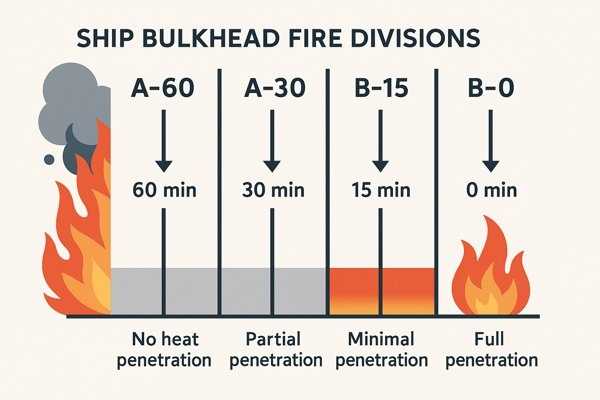

What are the differences among A-60, A-30, B-15 and B-0?

Is the difference between these fire ratings just a matter of time? While time is the most obvious factor, the core differences lie in their construction, insulation capabilities, and approved applications on a vessel.

The main difference lies in insulation. 'A' class divisions must be made of steel and prevent flame/smoke passage for 60 minutes, while 'B' class must only prevent flame passage for 30 minutes. The numbers (60, 30, 15, 0) indicate the minutes of insulation protection provided.

Let's break down the practical construction differences.

| Rating | Typical Construction | Primary Role | Analogy |

|---|---|---|---|

| A-60 | Steel bulkhead + 50-75mm pinned Rock Wool insulation. | Contain major fires; protect escape routes. | Bank Vault Door for Fire |

| A-30 | Steel bulkhead + 40-50mm pinned Rock Wool insulation. | Contain moderate fires; separate key areas. | Safe Deposit Box |

| B-15 | 50mm Rock Wool sandwich panel. | Contain a fire within a single cabin. | Standard Fire Door |

| B-0 | 25mm Rock Wool sandwich panel. | Divide spaces where heat transfer is not a risk. | Smoke Door |

Construction of A-Class Divisions

The key defining feature of an A-class division is that its structural core must be steel or an equivalent material. You cannot have an A-class division made just from a composite panel. It's typically a steel plate bulkhead (part of the ship's structure) with insulation attached to it.

Construction of B-Class Divisions

B-class divisions do not require a structural steel core; they can be constructed entirely from certified sandwich panels. Their job is to contain a fire within a single smaller compartment. Think of it as the fire door inside a building.

Applying the Right Fire Rating in Ship Design

I had a client from a ship interior decoration company who was very price-sensitive and wanted to use B-15 panels everywhere. I had to create a detailed drawing based on the ship's General Arrangement plan, marking exactly where A-60 divisions were legally required by SOLAS regulations—for example, surrounding the galley and laundry. Using the wrong rating isn't just a minor error; it would make the vessel unseaworthy and illegal to operate.

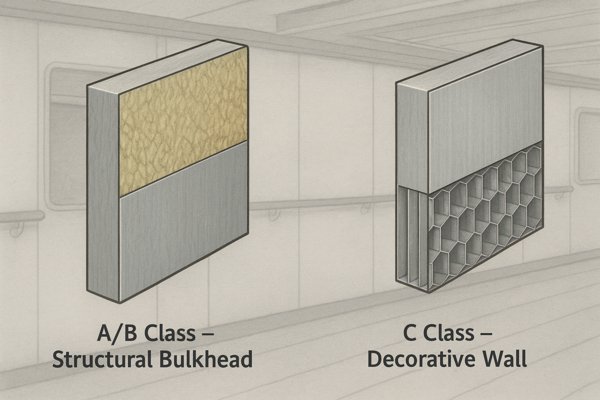

What are the main types of marine wall panels used for bulkheads versus decorative walls?

Do you need a structural, fire-rated wall, or just a decorative finish? The type of panel you choose will be completely different depending on whether it's for a load-bearing bulkhead or a simple aesthetic surface.

For structural bulkheads, sandwich panels with a rock wool core and steel surfaces (rated A or B class) are used. For purely decorative walls or linings, lightweight C-class panels, such as those with an aluminum honeycomb core, are common.

The function of the wall dictates its construction. Here is a direct comparison:

| Feature | Bulkhead Panel System (A/B-Class) | Decorative Panel (C-Class) |

|---|---|---|

| Primary Purpose | Safety (Fire & Sound) & Function | Aesthetics & Design |

| Certification | Mandatory (MED, USCG, etc.) | Non-combustible material certificate |

| Core Material | Rock Wool | Aluminum Honeycomb, Wood Veneer, HPL |

| Installation | Full system with rated profiles | Glued or fixed to an existing bulkhead |

| Main Application | Cabin walls, corridors, fire boundaries | Feature walls in lounges, suites, atriums |

Functional Panels: A/B-Class Bulkhead Systems

These are the panels that do the real work of division and fire protection. They are always part of a certified system, meaning the panel, profiles, and installation method are all tested and approved together. Their primary purpose is safety and functionality.

Aesthetic Panels: C-Class and Decorative Linings

These panels are all about aesthetics. A key part of my job is figuring out how to integrate these two types. A designer might want a seamless wood veneer wall in a lounge. Behind that veneer is a B-15 bulkhead with visible joints. We have to design the installation carefully, perhaps using a secondary framing system (called a sub-grid) to which the decorative panels are attached, creating a small gap for a clean, high-end look.

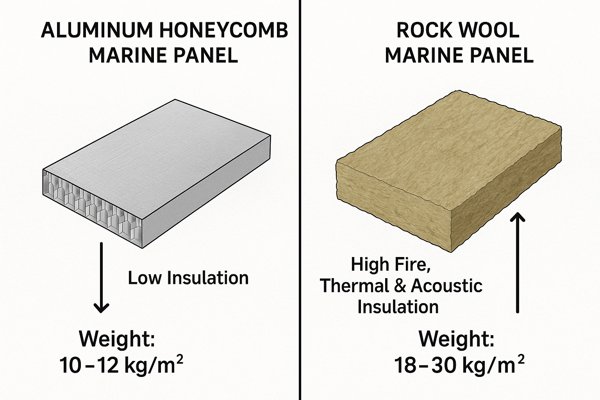

What are the weight and insulation properties of different types of marine panels?

Are you concerned about your ship's weight budget and energy efficiency? The choice of marine panel has a direct and significant impact on both of these critical factors.

Marine panels vary widely in weight and insulation. Aluminum honeycomb panels are the lightest, around 10-12 kg/m², but offer less insulation. Rock wool panels are heavier, 18-30 kg/m², but provide excellent fire, thermal, and acoustic insulation.

Let's look at some typical values and what they mean in practice. A 3dB increase in acoustic insulation represents a halving of the perceived sound energy. A lower U-value means better thermal insulation.

| Panel Type (Core Material) | Typical Weight (kg/m²) | Sound Reduction (Rw, dB) | Thermal Transmittance (U-value, W/m²K) |

|---|---|---|---|

| Aluminum Honeycomb (25mm) | 9 - 12 | ~30 | ~5.8 |

| Rock Wool (50mm) | 25 - 30 | ~33 | ~0.7 |

| PUF (50mm) | 12 - 18 | ~28 | ~0.4 |

| Calcium Silicate (25mm) | 20 - 35 | ~32 | ~0.9 |

The Weight Equation: A Practical Example

Every kilogram matters. Consider a small passenger ferry with 100 cabins, each with about 20 m² of internal partition walls.

- Using a 50mm Rock Wool panel (~28 kg/m²): 20 m²/cabin 100 cabins 28 kg/m² = 56,000 kg (56 tonnes).

- If these were non-rated C-class walls using 25mm Aluminum Honeycomb (~10 kg/m²): 20 m²/cabin 100 cabins 10 kg/m² = 20,000 kg (20 tonnes).

That's a 36-tonne difference. This directly impacts the ship's displacement, stability, and fuel consumption for its entire 25+ year lifespan.

Acoustic Performance and Crew Well-being

Achieving higher acoustic ratings (Rw 45dB+) often involves special techniques like using a "floating floor" system where the entire cabin floor is isolated from the steel deck with rubber mounts, or using constrained layer damping panels that have a viscoelastic layer to deaden vibration and noise. A quiet environment is critical for crew rest and preventing long-term hearing damage.

How are marine wall panels installed and secured within a vessel?

Worried about a complex and time-consuming installation process? Fortunately, marine wall panel systems are designed for efficiency, but proper technique is crucial for ensuring safety and performance.

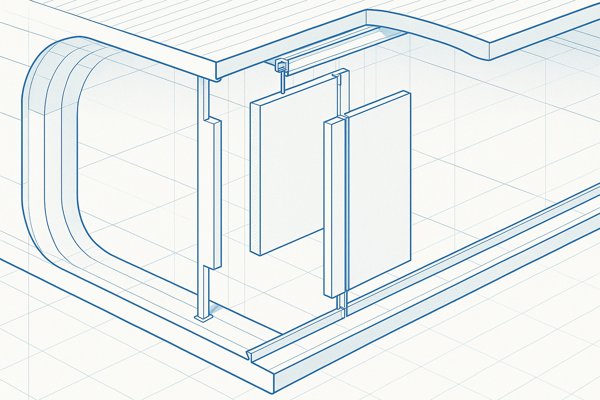

Marine wall panels are typically installed using a profile system. A bottom track is fixed to the deck and a top track to the ceiling. Panels are then slotted into these tracks and connected to each other using tongue-and-groove edges or special H-profiles.

Having overseen countless installations, I can tell you that a systematic approach is key.

Panel Connection Methods

The joining system is a critical choice, affecting installation speed and the final look.

| Joining System | Description | Speed | Aesthetics |

|---|---|---|---|

| Tongue-and-Groove | Panel edges interlock directly. | Fast | Seamless, clean |

| H-Profile | A separate 'H'-shaped profile connects two panels. | Slower | Visible joint line |

| Spline Joint | A thin metal strip joins grooves in both panels. | Moderate | Minimal joint line |

Common Installation Mistakes to Avoid

I've seen my share of installation errors that can compromise a multi-million dollar outfitting project.

- Improper Cutting: Using the wrong blade or a dull blade on a circular saw can chip the PVC finish and overheat the steel, damaging the galvanized coating at the edge and creating a future rust point.

- Incorrect Fasteners: Using the wrong type of screws or rivets can violate the fire certification. The certificate specifies exactly what fasteners must be used.

- Forcing Panels: If a panel is slightly too long, installers might try to hammer it into place. This can crush the rock wool core and damage the edges, weakening the panel and creating an imperfect joint. The rule is simple: measure twice, cut once.

How does one maintain and clean marine wall panels to prevent mold or damage?

Are you concerned about keeping your ship's interior looking pristine and hygienic? Proper maintenance of marine wall panels is simple but essential for preventing long-term damage, especially from moisture and mold.

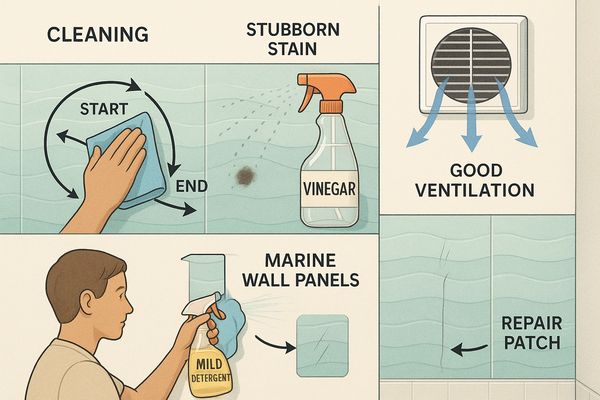

To maintain marine wall panels, regularly clean them with a soft cloth and a mild, non-abrasive detergent. For stubborn stains, use a diluted vinegar solution. Ensure good ventilation in wet areas and immediately repair any scratches or damage to the panel's surface.

From my experience, a consistent and gentle approach is the best way to preserve the look and integrity of these panels for years.

Routine Cleaning and Preventative Care

The key is to use the right tools and cleaners. For dust and light fingerprints, a dry or slightly damp microfiber cloth is perfect. For general cleaning, use a solution of warm water with a small amount of pH-neutral soap. Never use abrasive powders or harsh chemicals like bleach. Always wipe the panel dry with a clean cloth after washing to prevent water spots. In today's environment, regular disinfection is important. Use a disinfectant that is approved for use on PVC surfaces, as many harsh chemicals can damage the film.

Troubleshooting Common Maintenance Issues

Here is a quick guide to handling common problems.

| Problem | Likely Cause | Solution |

|---|---|---|

| Mold/Mildew Spots | High humidity, poor ventilation | Spray with a 50/50 water/vinegar solution, wait 1 hour, wipe clean. Improve ventilation. |

| Scuff Marks | Contact with luggage, carts, shoes | Try a pencil eraser first. If that fails, use a soft cloth with a tiny amount of isopropyl alcohol. |

| Peeling PVC at Edge | Moisture ingress, physical damage | Carefully dry the area, clean away any loose adhesive, and reseal the edge with a clear, marine-grade sealant. |

| Deep Scratches | Contact with sharp objects | Scratches exposing steel must be cleaned and touched up with manufacturer-supplied paint to prevent rust. |

Long-Term Inspection and Repair

The modular nature of these panels makes repairs relatively easy. If a panel is significantly damaged, it can often be replaced. The corner and joining profiles are removed, the damaged panel is taken out, a new one is cut to size and inserted, and the profiles are reinstalled. This is a huge advantage over traditional walls.

Conclusion

In summary, marine wall panels are engineered solutions vital for ship safety and comfort. They provide fire resistance, insulation, and durability in a lightweight, easy-to-install system, making them indispensable in modern shipbuilding.

-

Understanding Rw helps in designing quieter and more comfortable living spaces on ships. ↩

-

This test is vital for understanding how materials perform in corrosive environments, essential for marine safety. ↩

-

Understanding the ISO 834 standard fire curve is crucial for anyone involved in fire safety or construction, as it forms the basis for rating fire resistance in building materials. ↩