Are you struggling to find the right ceiling panels for your vessel? The unique demands of a marine environment can make choosing materials a real challenge. You need something that is not only stylish but also durable and compliant with strict safety regulations.

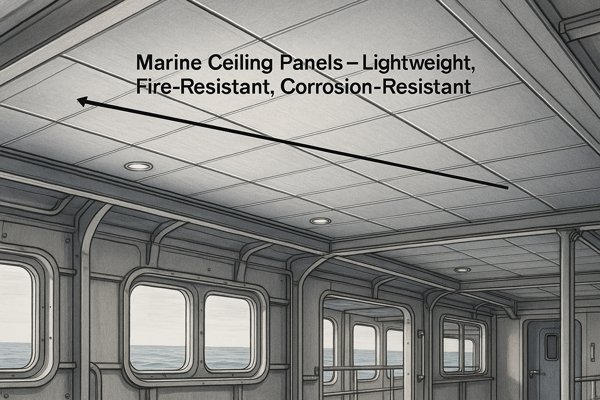

Marine ceiling panels are specialized panels designed for the ceilings of ships, boats, and offshore platforms. These panels are engineered to be lightweight, fire-resistant, and resistant to moisture and corrosion. They often come with certifications from bodies like the International Maritime Organization (IMO) to ensure they meet stringent safety standards for maritime use.

Choosing the right ceiling panel is crucial for both the safety and comfort of everyone on board. It’s not just about aesthetics; it’s about performance in a demanding environment that includes constant vibration, high humidity, and the potential for fire. In my years as a marine interior outfitting specialist, I've seen firsthand how the right choice of materials can make all the difference. Let me guide you through the key aspects of marine ceiling panels to help you make an informed decision for your project.

What Is The Difference Between A Marine Ceiling And A Standard Residential Ceiling?

Wondering if you can just use regular ceiling panels on your boat? The marine environment is far more demanding than a typical home, and standard materials just won't cut it. Using residential-grade panels can lead to safety hazards, rapid deterioration, and costly replacements down the line.

The primary difference lies in the materials, performance, and regulations. Marine ceiling panels are built to withstand moisture, salt spray, and constant movement. They must also meet strict fire safety codes, such as those set by the IMO, which are far more rigorous than those required for residential ceilings.

Comparing Marine and Residential Ceiling Features

Let's break down the key differences in a more structured way. When I work with clients, I always emphasize these points to ensure they understand why marine-grade is non-negotiable. Using the wrong product isn't just a compliance issue; it's a fundamental safety failure.

| Feature | Marine Ceiling | Standard Residential Ceiling |

|---|---|---|

| Fire Resistance | Must comply with strict IMO FTP Code (e.g., A, B, C-Class divisions). Core materials are non-combustible. | Typically has a basic fire rating (e.g., Class A per ASTM E84), but the core (gypsum) can degrade and fail in a high-intensity fire. |

| Moisture Resistance | High resistance to humidity, condensation, and salt spray. Made with non-corrosive materials like aluminum or galvanized steel and non-hygroscopic cores. | Susceptible to mold, mildew, and sagging. Gypsum and wood fiber cores will absorb moisture, lose structural integrity, and fail over time. |

| Core Materials | Rockwool, aluminum honeycomb, calcium silicate. | Gypsum, fiberglass, wood fiber. |

| Weight | Lightweight (e.g., 4-15 kg/m²) to maintain vessel stability and optimize fuel efficiency. | Weight is not a primary concern (e.g., gypsum can be 10-15 kg/m²). |

| Durability | Designed to withstand constant vibrations and structural flexing of the vessel without cracking or dislodging. | Not designed for constant movement. Panels and grids can easily become dislodged or damaged under such stress. |

| Certifications | Mandatory to have MED, USCG, or other Flag State authority approvals. | Certifications are typically related to building codes (e.g., UL) and are not valid for marine use. |

From my experience, a procurement officer from a ship interior decoration company in Indonesia once asked me if she could use a high-grade, moisture-resistant residential panel for a small yacht to save on costs. I explained that while it might look good initially, the first sign of rough seas or a surprise inspection would reveal the mistake. The constant flexing of the hull would cause the rigid gypsum panels to crack, and the high humidity would lead to sagging within a year. The cost of non-compliance and replacement far outweighs the initial savings.

What Are The Common Types Of Marine Ceiling Panels?

Feeling overwhelmed by the variety of marine ceiling panels available? It's easy to get lost in the technical jargon and endless options. Choosing the wrong type can lead to installation headaches and a finished product that doesn't meet the vessel's specific needs.

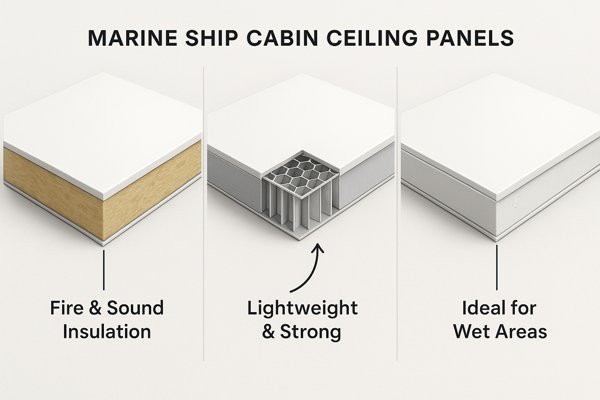

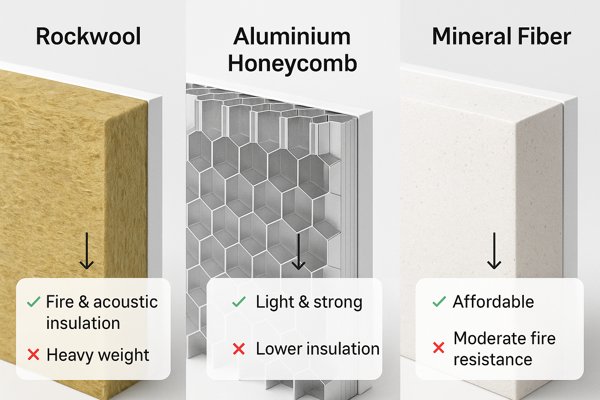

The most common types of marine ceiling panels are categorized by their core material and surface finish. These include rockwool core panels, known for their excellent fire and sound insulation; aluminum honeycomb panels, prized for their lightweight and high strength; and specialized PVC panels for wet areas.

A Detailed Look at Common Marine Ceiling Panel Types

The choice of panel often depends on the vessel type and the specific requirements of the space. Here is a summary of the main options:

| Panel Type | Core Material | Key Features | Best For |

|---|---|---|---|

| Rockwool Panels | Stone Wool | Excellent fire & acoustic insulation, cost-effective. | Accommodation, corridors, public spaces (B & A-Class). |

| Aluminum Honeycomb | Aluminum Honeycomb | Extremely lightweight, high strength-to-weight ratio. | High-speed craft, yachts, upper decks. |

| Calcium Silicate | Calcium Silicate | High fire resistance, thermally stable. | Core component for A-60 fire divisions. |

| PVC Hollow-Core | PVC | 100% waterproof, hygienic, easy to clean. | Wet areas like galleys, sanitary spaces, provision stores. |

I once worked on a project for a luxury yacht where the owner wanted a sleek, modern interior. We opted for aluminum honeycomb panels with a high-gloss HPL finish. The result was a stunning ceiling that was not only beautiful but also incredibly lightweight, which was crucial for the yacht's performance and stability.

What Are The Pros And Cons Of Different Core Materials For Ceiling Panels?

Choosing the right core material can feel like a high-stakes decision. The core of the panel dictates its performance in a fire, its weight, and its acoustic properties. Making the wrong choice can compromise safety, comfort, and the vessel's operational efficiency.

The main trade-offs between core materials are typically weight versus fire resistance and cost. For example, rockwool offers excellent fire and acoustic insulation but is heavier than aluminum honeycomb, which provides superior strength-to-weight performance but less insulation.

Comparing Core Materials: Rockwool vs. Aluminum Honeycomb vs. Calcium Silicate

Let's break down the pros and cons of the most common core materials I encounter in my work. This comparison will help you align a material's properties with your project's priorities.

Rockwool (Stone Wool)

A tried-and-true material made from volcanic rock fibers.

| Pros | Cons |

|---|---|

| Excellent fire resistance (non-combustible) | Heavier than other core materials (approx. 12-15 kg/m²) |

| Superior acoustic insulation properties | Can absorb moisture if facings are damaged |

| Good thermal insulation | Requires careful handling to avoid releasing airborne fibers |

| Cost-effective and widely available |

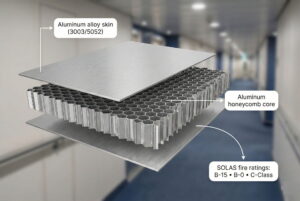

Aluminum Honeycomb

Thin aluminum sheets formed into a honeycomb structure.

| Pros | Cons |

|---|---|

| Extremely lightweight (approx. 4-6 kg/m²) | Most expensive option per square meter |

| Highest strength-to-weight ratio1 | Lower acoustic and thermal insulation properties |

| Completely resistant to moisture and corrosion | Face sheets can be prone to denting if very thin |

| Excellent for forming curved surfaces |

Calcium Silicate

A rigid board made from silicate and calcium materials.

| Pros | Cons |

|---|---|

| Excellent fire performance, forms the basis for A-Class divisions | Heavier and more brittle than other options |

| Very stable in high temperatures | Limited acoustic insulation properties |

| Good thermal insulation | Can be more difficult to cut and handle on site |

For many of my clients, the decision comes down to the vessel's primary function. For a commercial vessel or cruise ship, the fire rating, acoustic comfort, and cost-effectiveness of rockwool make it the best choice for accommodation areas. For a high-performance yacht, the weight savings from aluminum honeycomb are a significant advantage that directly impacts speed and fuel consumption.

What Are The Best Lightweight Ceiling Panels For A Yacht?

Are you outfitting a yacht and worried about adding unnecessary weight? Every kilogram counts on a performance vessel, as excess weight impacts speed, fuel efficiency, and stability. Finding a ceiling panel that is both lightweight and aesthetically pleasing is a primary challenge.

The best lightweight ceiling panels for a yacht are undoubtedly aluminum honeycomb panels. Their exceptional strength-to-weight ratio, which can be up to 75% lighter than traditional systems, makes them the ideal choice for performance-oriented vessels where minimizing weight is crucial without compromising on durability or a luxury finish.

Understanding Why Weight Matters for Yacht Ceilings

The data clearly shows why aluminum honeycomb is the preferred choice when weight is a critical factor.

| Panel Type | Typical Weight (kg/m²) | Impact |

|---|---|---|

| Aluminum Honeycomb | 4 - 6 kg/m² | Ideal for performance; lowers center of gravity, improves stability and fuel efficiency. |

| Composite (FRP) | 6 - 9 kg/m² | A good mid-range option, balancing weight and cost. |

| Rockwool Panel | 12 - 15 kg/m² | Too heavy for most performance yachts; better suited for commercial vessels. |

I remember a client who was refitting his racing yacht. He was adamant about shedding every possible gram. We replaced the existing, heavier ceiling panels with custom-made aluminum honeycomb panels. The weight savings were significant, and he was thrilled with both the performance improvement and the modern, clean look of the new ceiling.

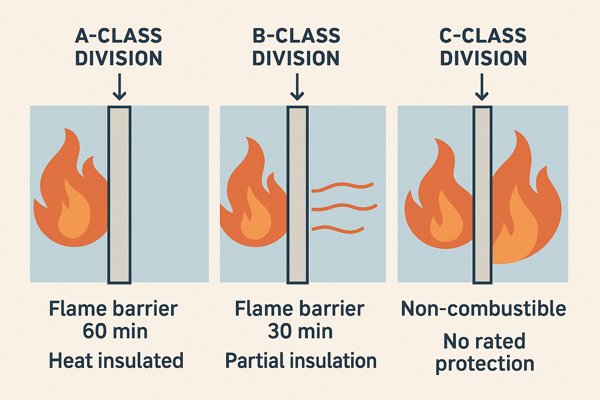

What Is The Difference Between A-Class, B-Class, And C-Class Divisions?

Navigating the complex world of maritime safety regulations can be daunting. You've likely come across the terms A-Class, B-Class, and C-Class, but what do they actually mean for your ceiling panels? Misunderstanding these classifications can lead to non-compliance and serious safety risks.

These classifications, defined by SOLAS, refer to the fire-resistance capabilities of bulkheads and decks. A-Class divisions offer the highest fire protection, preventing flame passage for 60 minutes and insulating against heat. B-Class offers a 30-minute flame barrier, and C-Class divisions are non-combustible but offer no rated protection time.

Defining A-Class, B-Class, and C-Class Fire Ratings

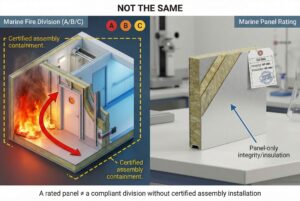

A ceiling panel is a component of a larger "division." The rating applies to the complete system, including the panel, insulation, and suspension grid.

| Class | Flame Barrier | Insulation (Temp Rise Limit*) | Core Material | Typical Application |

|---|---|---|---|---|

| A-60 | 60 minutes | 60 minutes | Steel or equivalent + Insulation | Main vertical zones, control stations, high-risk boundaries (e.g., galley, engine room) |

| A-30 | 60 minutes | 30 minutes | Steel or equivalent + Insulation | Boundaries with moderate risk |

| A-0 | 60 minutes | 0 minutes | Steel or equivalent | Lower risk boundaries where smoke/flame barrier is enough |

| B-15 | 30 minutes | 15 minutes | Non-combustible (e.g., Rockwool) | Cabin corridors, escape routes, stairways |

| B-0 | 30 minutes | 0 minutes | Non-combustible | Lower risk partitions |

| C-Class | No rating | No rating | Non-combustible | Linings, partitions in low-risk areas |

*Insulation limits the temperature rise on the unexposed side to 140°C on average.

For a practical example, the ceiling separating a passenger cabin from the main corridor (an escape route) would typically need to be part of a B-15 class division. The ceiling directly below the main galley (a high-risk area) would need to be part of an A-60 division to protect the space above from a fire below. The choice of panel is dictated by its role in creating these certified divisions.

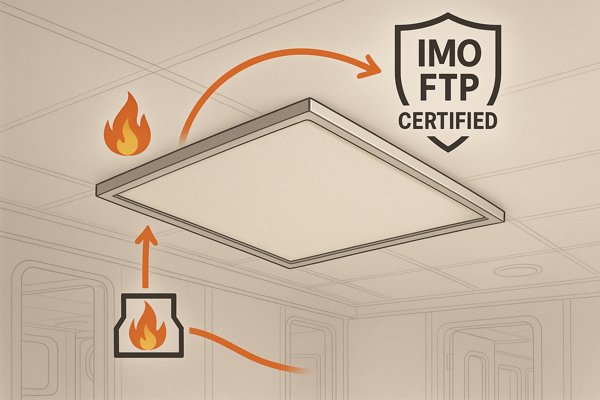

What Does An IMO FTP Code Certification Mean For Ceiling Panels?

Have you seen "IMO FTP Code Certified" on a product specification and wondered what it means? This certification is a critical indicator of a product's suitability for marine use, but the technicalities can be confusing. Using non-certified products is a risk you can't afford to take.

An IMO FTP Code certification signifies that a ceiling panel has passed the International Code for Application of Fire Test Procedures. This is the global standard, mandated by SOLAS, for ensuring materials won't contribute to a fire's spread, a crucial safety requirement for any SOLAS-compliant vessel.

Key Components of the IMO FTP Code for Ceiling Panels

To achieve certification, panels undergo a series of rigorous tests. Here are the most relevant parts for ceiling panels:

| FTP Code Part | Test Name | Purpose |

|---|---|---|

| Part 1 | Non-Combustibility | To ensure the core material itself will not burn or contribute fuel to a fire. |

| Part 2 | Smoke and Toxicity | To measure the amount and toxicity of smoke produced, ensuring escape routes remain tenable. |

| Part 3 | Test for "A" & "B" Class Divisions | The full-scale furnace test to determine the fire-resistance rating (e.g., A-60, B-15). |

| Part 5 | Test for Surface Flammability | To ensure decorative surface finishes will not contribute to the rapid spread of flames. |

I always tell my clients, particularly those involved in international shipping, that the IMO FTP Code certification2 is non-negotiable. It's the universal language of maritime fire safety. When a port state control officer boards your vessel, this is one of the first things they will look for. Having this certification ensures your vessel is compliant with global safety standards and can operate without issue in international waters.

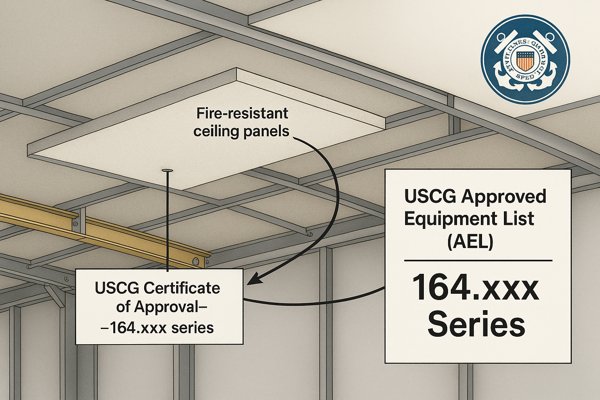

Which Ceiling Panels Are Approved By The US Coast Guard (USCG)?

Operating a vessel in US waters and need to ensure your materials are compliant? The US Coast Guard has its own set of stringent requirements, and navigating their approval process can be a major hurdle. Using unapproved materials can lead to costly refits and operational delays.

Ceiling panels approved by the USCG have a Certificate of Approval (COA) with a USCG approval number, found in the 164.xxx series for fire protection materials. These panels are tested to meet standards in Title 46 of the Code of Federal Regulations (CFR) and are listed on the USCG Approved Equipment List (AEL).

Key USCG Approval Numbers for Fire Protection

The USCG uses a numbering system to categorize approved materials. For ceilings and fire protection, these are the numbers to look for:

| Approval Series | Description of Material |

|---|---|

| 164.106 | A-Class Divisions (Bulkheads and Decks) |

| 164.107 | B-Class Ceilings |

| 164.108 | B-Class Doors |

| 164.109 | Non-combustible Materials |

| 164.112 | Interior Finishes (Surface Flammability) |

I often work with clients who are building or refitting vessels for the US market. I always stress the importance of checking for the USCG approval number on the product documentation. A few years ago, a client had to replace an entire section of ceilings on a new build because the supplier provided panels with IMO certification but not the specific USCG approval required for that vessel's route. It was a costly and time-consuming mistake that could have been easily avoided by a quick search on the AEL.

Which Ceiling Panels Are Approved By The MED?

Are you outfitting a vessel that will operate in European waters? Then you must be familiar with the Marine Equipment Directive (MED). The "Wheel Mark" of MED approval is a mandatory requirement, and failing to use compliant products can prevent your vessel from operating in the EU.

MED-approved ceiling panels are certified under the Marine Equipment Directive 2014/90/EU and bear the "Wheel Mark" of conformity. This mark signifies that the product meets the stringent safety requirements of the IMO and can be placed on any EU-flagged ship without further certification.

The Path to MED Approval for Marine Equipment

The Wheel Mark is a passport for marine equipment in the EU. It guarantees that the product has passed a rigorous two-stage approval process with a designated Notified Body.

| Step | Module | Description |

|---|---|---|

| 1. Design Approval | Module B: EC Type-Examination | A Notified Body reviews the product design, technical files, and fire test reports to confirm they meet IMO standards. |

| 2. Production Approval | Module D, E, or F: Quality Surveillance | The Notified Body regularly audits the manufacturer's factory and quality control systems to ensure ongoing production consistency. |

I recently helped a procurement officer who was sourcing materials for a series of ferries to be built in China but flagged in an EU country. She was focused on finding high-quality, cost-effective panels. I guided her to a supplier whose rockwool and aluminum honeycomb panels were both MED-certified. This ensured that her company's projects would be fully compliant, avoiding any potential issues with European maritime authorities. For anyone involved in the European shipbuilding market, insisting on the MED Wheel Mark is standard practice.

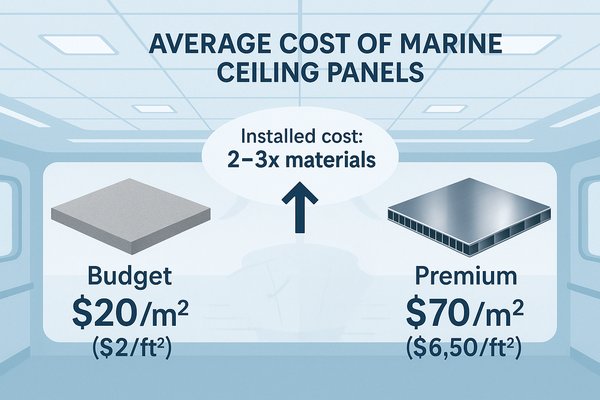

What Is The Average Cost Of Marine Ceiling Panels Per Square Meter/Foot?

Trying to budget for your marine interior project? The cost of ceiling panels can vary widely, and getting a clear price estimate is often a challenge. Without accurate cost data, you risk under-budgeting and facing unexpected expenses.

The average material cost for marine ceiling panels ranges from $20 to $70 per square meter ($2 to $6.50 per square foot). The final installed cost, including the grid and labor, can be 2 to 3 times the material cost. Rockwool panels are most budget-friendly, while aluminum honeycomb is a premium option.

Understanding the Total Cost of Marine Ceilings

Here is a more detailed cost breakdown for the panel material only. Prices vary based on supplier, volume, and specific certifications.

| Panel Type | Average Cost (per m²) | Average Cost (per ft²) | Key Cost Factors |

|---|---|---|---|

| Rockwool Core Panel | $17 - $30 | $1.60 - $2.80 | Thickness (B-15 vs. A-60), surface finish (PVC vs. Steel) |

| Aluminum Honeycomb | $40 - $70+ | $3.70 - $6.50+ | Core density, face sheet thickness, surface finish (HPL is extra) |

| Calcium Silicate Board | $25 - $45 | $2.30 - $4.20 | Thickness, density |

I always remind clients that the panel itself is just one part of the cost. You also need to factor in the suspension grid, installation labor, and shipping. A project quoted at $25/m² for materials could easily become $60/m² or more once fully installed. Always budget for the complete, installed cost.

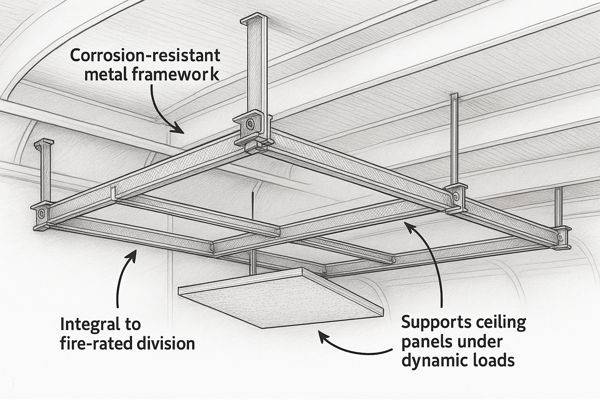

What Are Marine Ceiling Suspension Grids?

Planning your ceiling installation and wondering how the panels stay up? The suspension grid is the unsung hero of a marine ceiling system. Using the wrong type of grid can lead to a weak, corroded, or non-compliant installation.

A marine ceiling suspension grid is a metal framework used to support the ceiling panels. Unlike standard commercial grids, marine grids are designed to be corrosion-resistant, lightweight, and strong enough to withstand the vibrations and dynamic loads of a vessel at sea. The grid is an integral part of the fire-rated division.

Comparing Exposed vs. Concealed Ceiling Grid Systems

The two primary types of grid systems offer different aesthetics and functionality.

| Feature | Exposed Grid (Lay-in) | Concealed Grid (Clip-in) |

|---|---|---|

| Appearance | Grid is visible, creating a tiled look. | Grid is hidden, providing a smooth, monolithic surface. |

| Accessibility | Excellent; panels can be easily lifted for access to the plenum. | Limited; requires special tools to remove panels. |

| Installation | Faster and simpler to install. | More complex and time-consuming. |

| Best For | Control rooms, service areas, or where frequent access is needed. | Passenger cabins, public areas, and where aesthetics are a priority. |

I once saw an installation on a coastal vessel where a standard grid had been used to save money. Within a year, the grid was showing significant signs of rust, and the entire ceiling had to be replaced. The marine environment is relentless, and using purpose-built, corrosion-resistant materials3 is the only way to ensure a lasting and safe installation.

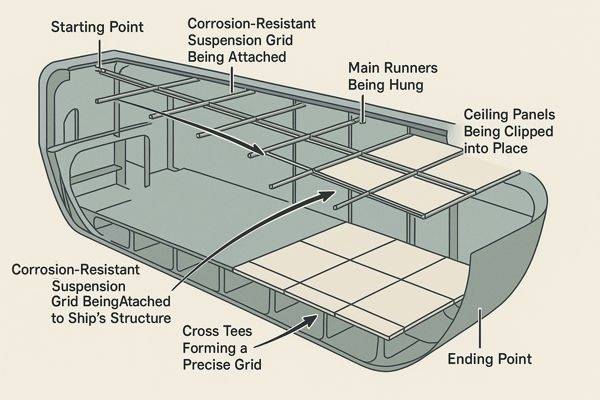

How Is A Marine Ceiling Panel System Installed?

Ready to install your marine ceiling, but not sure where to start? Proper installation is critical for safety, compliance, and aesthetics. A poorly installed ceiling can fail under stress, violate safety codes, and look unprofessional, ultimately costing you more in the long run.

A marine ceiling panel system is installed by first fitting a corrosion-resistant suspension grid to the ship's structure. Main runners are hung, cross tees form the grid, and then panels are carefully placed or clipped into the framework. Precision is key to ensuring compliance and a professional finish.

Installation Checklist for Marine Ceilings

Before starting, ensure you have the right tools and materials. A proper setup prevents mistakes and delays.

| Category | Essential Items |

|---|---|

| Layout Tools | Laser level, chalk line, measuring tape, square. |

| Cutting Tools | Circular saw (with fine-tooth/metal blade), snips, utility knife. |

| Fastening Tools | Drill, appropriate fasteners for ship structure. |

| Grid Components | Wall angle, main runners, cross tees, hanger wires/rods, clips. |

| Panels | The certified ceiling panels for the project. |

| Safety Gear | Safety glasses, gloves, dust mask. |

I always tell my installation teams that precision is key. Taking the time to get the layout and grid perfectly level and square at the beginning saves a huge amount of time and frustration later. The most common installation mistake is not squaring the grid. A square grid ensures all panels fit perfectly and the final appearance is professional.

How Are Marine Ceiling Panels Cut?

Need to cut marine ceiling panels to size for borders or fixtures? Cutting these specialized panels can be tricky. Using the wrong tool or technique can result in chipped edges, delamination, or an inaccurate cut, ruining expensive materials.

Marine ceiling panels are cut using saws with fine-toothed blades. A circular saw is effective for rockwool panels, while a bandsaw or router is better for aluminum honeycomb. The key to a clean cut is a sharp blade, proper support, and a steady hand.

Quick Reference Cutting Guide for Marine Panels

Use this table as a quick guide for achieving the best results.

| Panel Core Material | Recommended Tool | Key Tip |

|---|---|---|

| Rockwool | Circular Saw with fine-tooth blade. | Cut with the decorative face down to prevent chipping. Seal cut edges with foil tape. |

| Aluminum Honeycomb | Bandsaw or Router. | Use a slow, steady feed rate to avoid tearing the core. Deburr edges with a file. |

| Calcium Silicate | Circular Saw with carbide/diamond blade. | Cut outdoors if possible due to dust. Wear a dust mask. |

| PVC Hollow-Core | Fine-toothed hand saw or circular saw. | Cuts easily, but a fine blade prevents melting or rough edges. |

From my years in the factory and on-site, I've learned that the right technique is just as important as the right tool. Always wear your PPE, especially safety glasses and a dust mask.

How Is A Damaged Boat Ceiling Panel Replaced?

Have you discovered a stained, dented, or otherwise damaged ceiling panel on your boat? A single damaged panel can ruin the look of an entire cabin. The good news is that in a suspended ceiling system, you don't have to replace the entire ceiling.

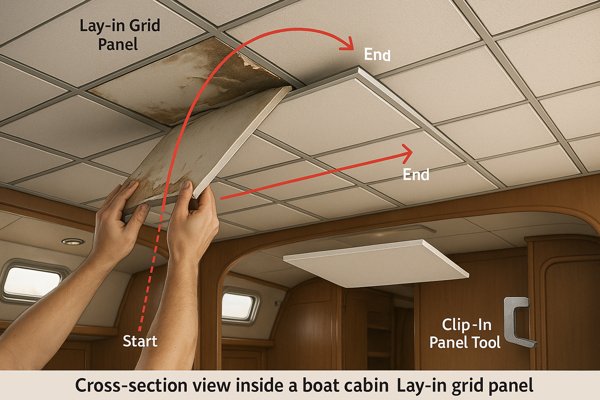

Replacing a damaged boat ceiling panel in a lay-in grid system is straightforward: simply push the old panel up, tilt it, and remove it from the grid. Then, insert the new panel. For concealed or clip-in systems, you may need a special tool to release the damaged panel before clipping a new one into place.

Panel Replacement Methods at a Glance

The method depends entirely on your grid system.

| System Type | Removal Method |

|---|---|

| Exposed (Lay-in) | Simple manual removal. Push the panel up, tilt it, and lower it through the grid opening. No tools needed. |

| Concealed (Clip-in) | Requires a special demounting tool. The thin tool is inserted into the joint to release the clips holding the panel. |

Before replacing any panel, it's crucial to identify and fix the root cause of the damage. I've seen people replace a water-stained panel only to have the new one stained a few weeks later because the underlying problem wasn't addressed. I also advise clients to order 5-10% extra panels with the initial project to keep as perfectly color-matched spares for future repairs.

How Are Marine Ceiling Panels Maintained And Cleaned?

Are your boat's ceiling panels looking a bit grimy or dull? The marine environment can be tough on interior surfaces. Proper cleaning and maintenance are essential to keep your ceiling looking its best and to prolong its lifespan.

Marine ceiling panels, especially those with a PVC or painted finish, should be cleaned with a soft cloth or sponge using a mild, non-abrasive detergent diluted in warm water. Avoid harsh chemicals, solvents, or abrasive cleaners, as these can permanently damage the panel's surface.

Cleaning Do's and Don'ts for Marine Ceilings

Follow these simple rules to keep your ceiling looking new without causing damage.

| Do Use | Do NOT Use |

|---|---|

| Soft cloths or sponges | Abrasive pads, steel wool, or hard-bristle brushes |

| Mild, pH-neutral detergent (e.g., dish soap) | Harsh chemicals (bleach, ammonia, strong solvents) |

| A well-wrung-out, damp cloth | Excessive water or pressure washers |

| A gentle wiping motion | Aggressive scrubbing |

| A "magic eraser" (gently) for scuffs | Abrasive powdered cleaners (e.g., Comet) |

I always advise my clients to do a spot test on a small, inconspicuous area before cleaning the entire ceiling with a new cleaning product. This simple precaution can prevent a major disaster. With just a little bit of care, your marine ceiling panels will continue to look great for many years.

Conclusion

In short, selecting the right marine ceiling panels requires a careful balance of fire safety, weight, durability, and cost. Using certified, professionally installed systems is non-negotiable for a safe and compliant vessel.

-

Exploring this concept can enhance your knowledge of material efficiency and performance. ↩

-

Understanding the significance of IMO FTP Code certification is crucial for compliance and safety in international shipping. ↩

-

Explore this link to learn about materials that ensure durability and longevity in challenging environments. ↩