Struggling to select the right wall panels for your ship's interior? Choosing wrong can lead to costly compliance issues and an unsafe environment for the crew and passengers.

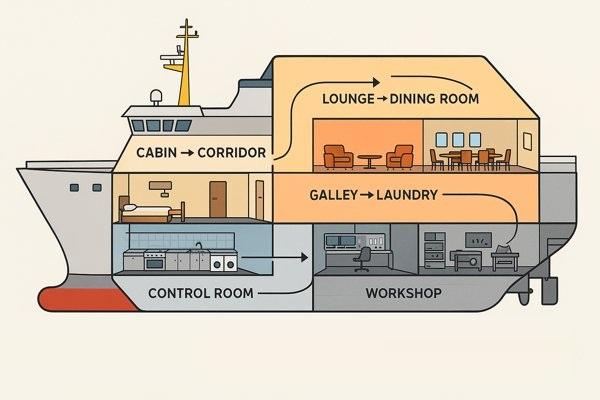

Marine wall panels are used in nearly every enclosed space on a ship. This includes accommodation areas (cabins, corridors), public spaces (lounges, dining rooms), service areas (galleys, laundries), and technical spaces (control rooms, workshops), with the panel type chosen based on the area's specific requirements.

I remember a client from Indonesia, a sharp procurement officer, who was in a tough spot. She was outfitting a new cruise ship and the initial wall panel selections were a mess. The fire ratings were incorrect for the galley, and the acoustic insulation in the cabins was not up to standard. We had to work together to rectify these issues, which caused significant delays. This experience taught me the critical importance of understanding where and why specific marine wall panels are used. Let me share what I've learned to help you avoid similar problems.

What Are The Different Types Of Marine Wall Panels?

Feeling overwhelmed by the variety of marine wall panels available? It's easy to get lost in the technical jargon and make a choice that isn't optimal for your project.

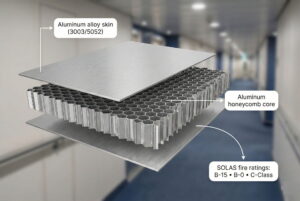

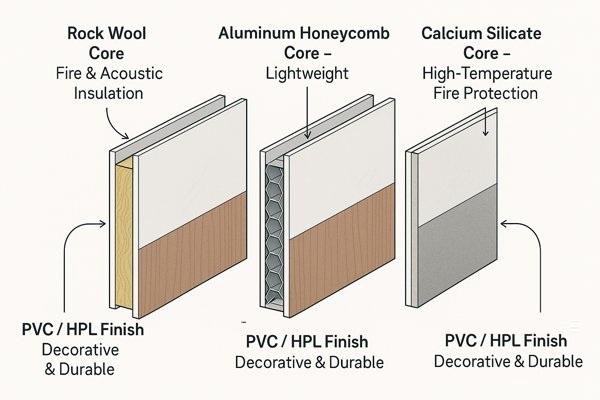

The most common types are defined by their core: rock wool panels for fire/acoustic insulation, aluminum honeycomb panels for saving weight, and calcium silicate panels for high-temperature fire divisions. Surface finishes like PVC or HPL are added for decoration and durability.

Understanding Panel Core Materials and Surface Finishes1

Choosing the right panel is a two-part decision: the core and the surface. The core material dictates the panel's fire and acoustic performance, while the surface finish determines its look and durability in its intended environment.

- Core Materials: Rock wool is the all-rounder for fire and sound, while aluminum honeycomb is for weight-sensitive applications.

- Surface Finishes: This is what you see and touch. The most common options include PVC film, High-Pressure Laminate (HPL), and various steel finishes. The table below summarizes their characteristics.

| Surface Finish | Key Characteristics | Best For |

|---|---|---|

| PVC Film | Cost-effective, wide variety of colors/patterns, easy to clean. | Cabins, corridors, standard accommodation spaces. |

| HPL | Highly durable, scratch and impact resistant, long lifespan. | High-traffic areas, mess rooms, doors, public spaces. |

| Painted Steel | Functional, durable, simple baked-on paint finish. | Crew areas, workshops, storerooms. |

| Stainless Steel | Hygienic, heat and corrosion resistant, very durable. | Galleys, food preparation areas, hospital facilities. |

Weight is another critical factor. A standard 50mm rock wool panel (with a core density of ~150 kg/m³) weighs about 18-20 kg/m². In contrast, a 25mm aluminum honeycomb panel might weigh only 6.5 kg/m². For a large superstructure, this weight difference adds up to hundreds of tons, affecting the ship's stability and fuel efficiency.

What Is The Difference Between A, B, And C-Class Divisions In Shipbuilding?

Confused by the A, B, and C-class divisions in maritime regulations? Misunderstanding these classifications can lead to non-compliance and serious safety hazards on board.

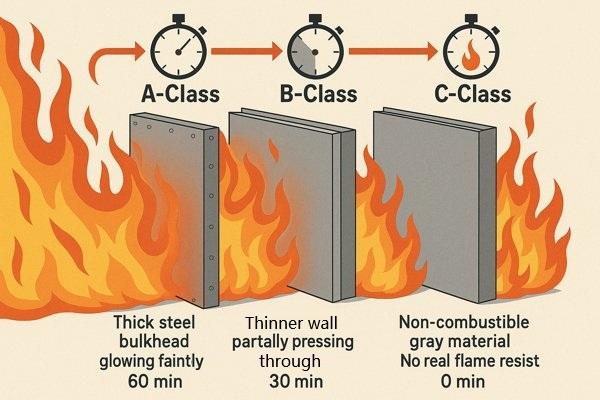

A, B, and C-class divisions are fire ratings. A-class stops flames for 60 minutes and limits heat transfer for a set time (e.g., 60 min for A-60). B-class stops flames for 30 minutes. C-class is made of non-combustible materials but offers no rated fire barrier.

Why A and B-Class Divisions Limit Heat Transfer

The core purpose of these classes is compartmentation—keeping a fire contained. The passage of flame is an obvious danger, but the limitation on temperature rise is just as critical. A fire can heat a steel bulkhead to several hundred degrees, and materials on the "safe" side can auto-ignite from this heat alone. The SOLAS rule preventing the unexposed side from rising more than 140°C above ambient provides a crucial safety margin. The table below provides a clear summary of the requirements for each class.

| Division Class | Construction Material | Flame Passage Prevention | Max Avg. Temp Rise | Insulation Duration |

|---|---|---|---|---|

| A-60 | Steel or equivalent | 60 minutes | 140°C | 60 minutes |

| A-30 | Steel or equivalent | 60 minutes | 140°C | 30 minutes |

| A-15 | Steel or equivalent | 60 minutes | 140°C | 15 minutes |

| A-0 | Steel or equivalent | 60 minutes | No limit | 0 minutes |

| B-15 | Non-combustible | 30 minutes | 140°C | 15 minutes |

| B-0 | Non-combustible | 30 minutes | No limit | 0 minutes |

| C-Class | Non-combustible | No requirement | No limit | N/A |

What Fire Ratings Are Required For Wall Panels In Different Ship Areas?

Unsure about the specific fire ratings needed for different areas of your ship? A mistake here can have dire consequences, both in terms of safety and regulatory approval.

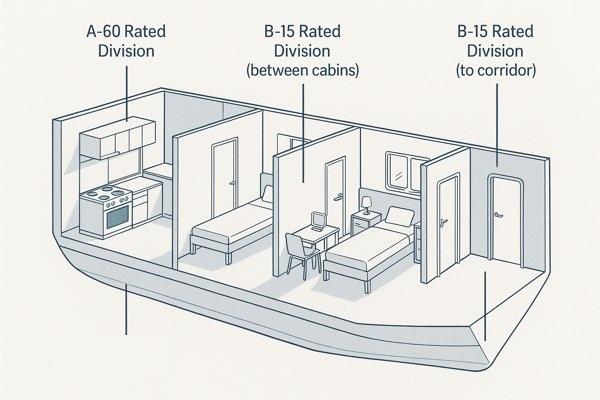

High-risk areas like galleys and machinery spaces require A-60 rated divisions. Accommodation spaces are typically separated from each other by B-15 divisions, and from corridors by B-15 divisions. Always check the ship's specific fire control plan for exact requirements.

How Fire Risk Determines Required Panel Ratings

The SOLAS fire rating tables are based on a logical risk assessment, evaluating the Fire Load2 (combustible material) and Ignition Sources in adjacent spaces.

Let's apply this logic:

- Galley to Accommodation: High risk next to medium risk. The galley has a high fire load (cooking oil) and many ignition sources. The boundary must be A-60 to provide maximum protection.

- Cabin to Corridor: Medium risk next to low risk. The cabin has a fire load, but the corridor is an essential escape route. The boundary must be B-15 to maintain the integrity of the escape route.

- Cabin to Cabin: Medium risk next to medium risk. A B-15 division is sufficient to contain a fire in one cabin long enough for alarms to sound.

The table below from SOLAS Chapter II-2, Regulation 9 gives a general overview.

| Adjacent Spaces | Control Stations | Stairways | Corridors | Accommodation Spaces | Machinery Spaces | Galleys |

|---|---|---|---|---|---|---|

| Control Stations | A-0 | A-0 | A-0 | A-60 | A-60 | A-60 |

| Stairways | A-0 | A-0 | A-0 | A-0 | A-60 | A-15 |

| Corridors | A-0 | A-0 | B-15 | B-15 | A-60 | A-30 |

| Accommodation | A-60 | A-0 | B-15 | B-15 / A-0* | A-60 | A-60 |

| Machinery Spaces | A-60 | A-60 | A-60 | A-60 | A-60** | A-60 |

| Galleys | A-60 | A-15 | A-30 | A-60 | A-60 | A-0 |

(Note: Requirements can vary. Always consult the ship's specific fire control plan.)

What Are The Acoustic Insulation Requirements For Wall Panels On A Ship?

Concerned about noise levels on your vessel? Inadequate acoustic insulation can lead to crew fatigue, passenger discomfort, and failure to meet maritime noise level regulations.

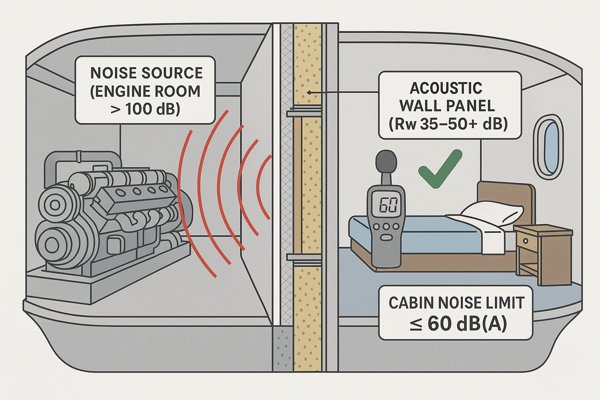

Acoustic requirements aim for specific noise levels, like a maximum of 60 dB(A) in cabins. To achieve this, panels and wall systems are selected based on their Sound Reduction (Rw) rating, typically requiring an Rw of 35 dB to over 50 dB depending on the adjacent space.

Airborne vs. Structure-Borne Noise

To choose the right solution, it's important to understand airborne noise (e.g., voices) and structure-borne noise (e.g., engine vibration). Standard panels are effective against airborne noise, but structure-borne noise requires special resilient mounting techniques. The IMO Noise Code and MLC 2006 set limits to ensure crew can rest, often around 60 dB(A) in cabins. If an adjacent space produces 100 dB(A), the partition must provide at least 40 dB of sound reduction. The performance of different panel systems varies significantly.

| Panel / Wall System | Typical Thickness | Typical Sound Reduction (Rw) | Best Use Case |

|---|---|---|---|

| Single 50mm Panel | 50 mm | 33-35 dB | Standard cabin-to-cabin partitions. |

| Single 75mm Panel | 75 mm | 38-40 dB | Partitions requiring better-than-standard insulation. |

| Double Wall System | 125-150 mm (total) | 45-55 dB | Between cabins and noisy corridors or public spaces. |

| Resiliently Mounted Wall | Varies | >50 dB | Partitions adjoining high-noise areas like engine casings. |

How Is Soundproofing Achieved With Marine Acoustic Panels?

Wondering how marine acoustic panels actually work to reduce noise? Understanding the principles behind soundproofing will help you select the most effective solutions for your vessel.

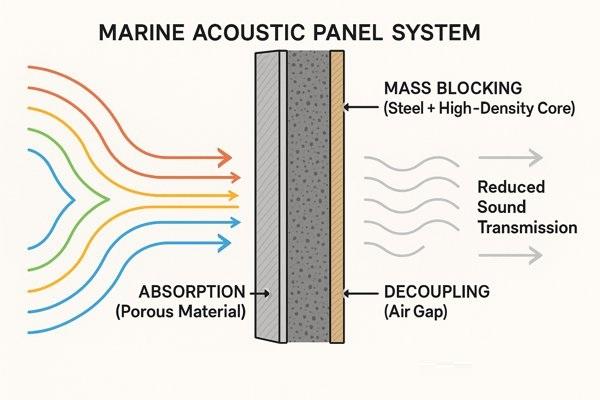

Marine acoustic panels work in two ways: their high-density core and steel faces provide mass to block sound from passing through, while the porous core material provides absorption to reduce sound energy and echoes. High-performance systems add decoupling (air gaps) to further improve insulation.

The Science Behind Acoustic Panel Performance

Let's look at a standard 50mm rock wool sandwich panel. It achieves its Rw 33 dB rating through a combination of scientific principles. Mass Law3 states that doubling a barrier's mass improves insulation by about 5-6 dB; the panel's steel faces provide this mass. The rock wool core provides absorption, converting sound energy into heat. Finally, the composite nature of the panel helps to damp natural resonance, where the panel might otherwise vibrate and transmit sound easily. To achieve a higher rating, like Rw 45 dB, you can't just use a single panel. You would typically need a double-wall system. This involves two separate panel walls with an air gap of 50-100mm in between. This air gap effectively "decouples" the two walls, making it very difficult for sound to travel from one to the other. This is the gold standard for acoustic privacy.

Which Marine Wall Panels Are Best For Wet Areas Like Bathrooms And Galleys?

Dealing with moisture and humidity in wet areas on a ship? Choosing the wrong wall panels can lead to mold, mildew, and other problems that are difficult and expensive to fix.

For wet areas like galleys and bathrooms, use panels with a completely impervious surface. Stainless steel is best for galleys due to hygiene and durability. PVC-coated steel panels or complete prefabricated wet units are ideal for bathrooms, ensuring a fully sealed, water-resistant environment.

Comparing Individual Panels vs. Prefabricated Wet Units

While using individual panels is an option, the industry standard for new builds is often the prefabricated wet unit—a complete, factory-built bathroom pod. This method offers superior quality control and speeds up outfitting. The choice depends on the project's budget, timeline, and quality requirements.

| Solution | Durability | Installation | Hygiene | Initial Cost |

|---|---|---|---|---|

| PVC-Coated Steel Panels | Good | On-site, requires skilled labor for sealing. | Good, but joints can be a weak point. | Medium |

| Stainless Steel Panels | Excellent | On-site, more complex to install. | Excellent, seamless surfaces possible. | High |

| Prefabricated Wet Unit | Excellent | Fast, plug-and-play installation on ship. | Excellent, seamless floor-to-wall coving. | High |

For a procurement officer, specifying prefabricated wet units can save significant time and reduce the risk of future leaks and warranty claims, often justifying the higher initial cost.

What Are The International Standards And Certifications For Marine Wall Panels?

Navigating the complex world of maritime certifications can be a daunting task. How can you be sure that the wall panels you're purchasing meet all the necessary international standards?

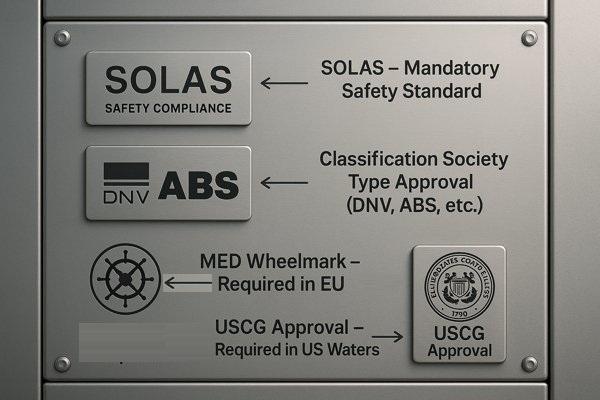

All panels must comply with SOLAS and have Classification Society Type Approval (e.g., DNV, ABS). For ships in the EU, they must have the MED Wheelmark. For ships in US waters, they need USCG approval. Always ask the supplier for these specific certificates.

Navigating Global Certifications: MED, USCG, and Class

While SOLAS provides the global baseline, you need to be aware of other approvals depending on the ship's flag state and where it will operate. As a procurement officer, you must check which certificates your supplier needs to provide.

| Certification | What It Is | When It Is Required |

|---|---|---|

| SOLAS / FTP Code | The international safety rules for fire protection. | Always. This is the global baseline for all ships. |

| Class Approval | Type approval from a society like DNV, ABS, LR, BV. | Always. Must match the classification society of the ship. |

| MED Wheelmark | A certification for the European Union market. | Mandatory for all equipment on EU-flagged ships. |

| USCG Approval | Approval from the United States Coast Guard. | Mandatory for most vessels operating in U.S. waters. |

How Are Marine Wall Panels Certified For Maritime Use?

Ever wondered what it takes for a marine wall panel to get that all-important certification? Understanding the process can give you a better appreciation for the quality and safety standards.

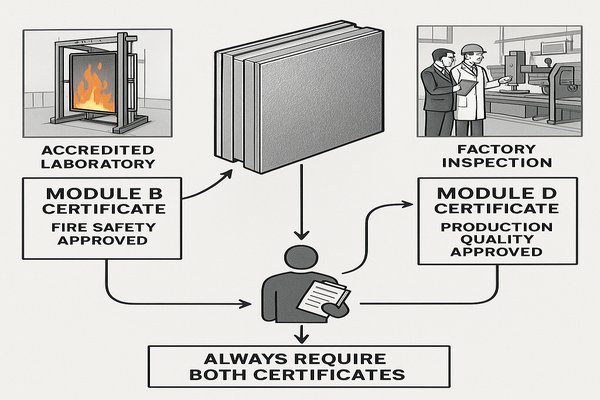

Panels are certified through a Type Approval process. This involves a successful fire test at an accredited lab (Module B certificate) and a factory production audit to ensure consistent quality (Module D certificate). A buyer should always require both certificates from their supplier.

The Role of Factory Audits (Module D) in Certification

Getting a Type Approval Certificate (MED Module B) is only half the story. To maintain it, the manufacturer must also have a certified Quality Management System, covered by MED Module D (Production Quality Assurance). This ensures every panel produced is identical to the one that was tested.

The general steps for certification are outlined below.

| Step | Action | Purpose |

|---|---|---|

| 1. Application | Manufacturer submits technical drawings and specifications. | To allow for initial design review against regulations. |

| 2. Testing | A sample panel is built and undergoes a fire test at a lab. | To prove the design meets the required fire rating (e.g., A-60). |

| 3. Factory Audit | A surveyor inspects the factory and quality control system. | To ensure consistent production quality (Module D). |

| 4. Certification | The society issues Module B and Module D certificates. | To officially approve the product and production for maritime use. |

Always ask a supplier for both the Module B (design) and Module D (quality) certificates.

How Are Marine Wall Panels Installed On A Ship?

Curious about how marine wall panels are fitted on a ship? Understanding the installation process can help you better plan your outfitting projects and communicate with your installation teams.

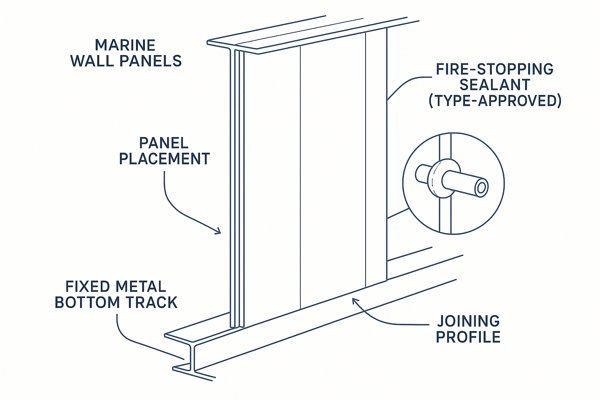

Panels are installed using a metal profile system. A bottom track is fixed to the deck, panels are placed in it, and joining profiles connect them. The most critical step is to properly seal all pipe and cable penetrations with type-approved fire-stopping materials.

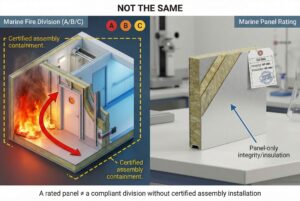

Why Proper Installation and Penetration Sealing are Crucial

A certified A-60 panel is useless if it's installed incorrectly. The fire rating applies to the entire system. This includes the various galvanized steel profiles used to build the wall.

| Profile Type | Description | Primary Function |

|---|---|---|

| Bottom Track | A "U" shaped profile fixed to the deck. | Secures the base of the panels and aligns the wall. |

| Corner Profile | An "L" shaped profile. | Used to start a wall and form internal or external corners. |

| H-Profile | An "H" shaped profile. | Slides between two panels to join them securely and cover the seam. |

| Omega Profile | A stiffening profile mounted on the panel surface. | Provides a strong point for attaching heavy furniture or fixtures. |

The most common point of failure is an unsealed penetration. Any pipe, duct, or cable must be sealed with a type-approved fire-stopping system, such as a fire collar or fire-rated sealant. An unsealed hole can cause an A-60 bulkhead to fail a fire test in minutes.

Conclusion

Selecting the right marine wall panels is a critical aspect of ship interior outfitting. By understanding the different types, their properties, and the relevant regulations, you can ensure the safety, comfort, and compliance of your vessel.

-

Discover the benefits of various surface finishes to make informed choices for durability and aesthetics in your projects. ↩

-

Understanding Fire Load is crucial for assessing fire risks and ensuring safety compliance in various environments. ↩

-

Understanding Mass Law is crucial for optimizing sound insulation in various environments, making this resource invaluable. ↩