Struggling to find a material that is tough, good-looking, and affordable for your marine interior project? The search can be frustrating, leaving you worried about durability, compliance, and long-term costs.

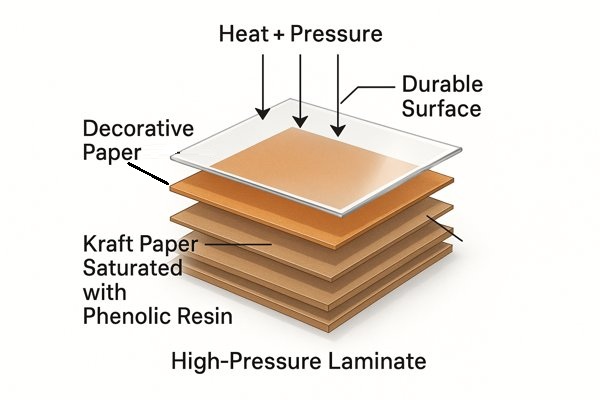

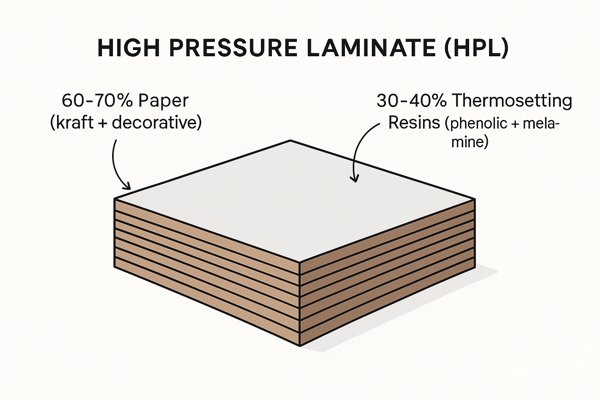

High Pressure Laminate (HPL) is a decorative surface material made from layers of kraft paper saturated with phenolic resin and a decorative paper layer fused together under intense heat and pressure. This process creates a durable, versatile, and decorative panel perfect for demanding environments like ship interiors.

I've been in the marine interior outfitting business for years, from my start in a factory to my current role as a specialist. I've seen many clients wrestle with material selection. They need something that can stand up to the harsh marine environment but also meets aesthetic and budget requirements. Let's dive deep into High Pressure Laminate, a material I've often recommended to solve these exact problems.

How is High Pressure Laminate made?

Are you concerned about how a seemingly simple sheet can be so strong? Understanding its creation is key to trusting its performance in your projects, especially when supplier claims seem too good to be true.

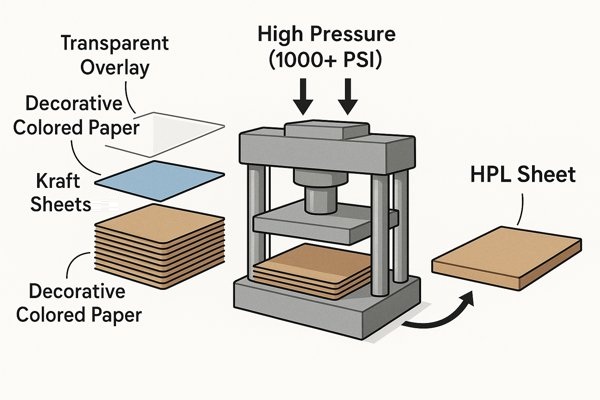

HPL is made by pressing multiple layers of resin-impregnated kraft paper and a decorative paper layer under high pressure (over 1,000 PSI) and high temperature (around 280-320°F or 140-160°C). This process, called thermosetting, permanently fuses the layers into a single, dense, and rigid sheet.

The manufacturing process is a marvel of material science, turning simple paper and resin into an industrial-strength decorative surface. It's a precise, multi-step process.

Step 1: Creating the Resin-Soaked Core

It all starts with responsibly sourced kraft paper. Multiple sheets are soaked in phenolic resin1, a powerful thermosetting plastic. This resin is the heart of the material's rigidity, impact resistance, and dimensional stability. The number of kraft paper layers dictates the final thickness of the laminate.

Step 2: Adding the Decorative Surface

On top of the core layers, a decorative paper is placed. This is the visual surface, which can be a solid color or a highly realistic printed pattern mimicking wood, stone, or metal. This paper is saturated with melamine resin2, an incredibly hard and clear thermosetting resin that provides the surface with its primary resistance to scratches, chemicals, and heat.

Step 3: Fusing Layers with Heat and Pressure

The "sandwich" of resin-soaked papers is placed into a large press under intense pressure (1,000 - 1,400 PSI) and high heat. This activates the resins, causing them to flow and cross-link into a single, solid sheet. The texture of the final surface—whether gloss or matte—is imparted by a textured steel press plate during this stage.

What is HPL composed of?

Worried about what's actually in the materials you specify? It's a valid concern, especially with increasing regulations and a focus on health and safety in enclosed marine environments.

High Pressure Laminate is primarily composed of about 60-70% paper (kraft paper for the core and decorative paper for the surface) and 30-40% thermosetting resins (phenolic resin for the core and melamine resin for the surface layer).

The specific combination of these materials is what gives HPL its unique properties. It's a composite material where each component plays a critical role.

The Role of Each Component in HPL

| Component | Material | Function | Percentage (Approx.) |

|---|---|---|---|

| Core Layers | Kraft Paper | Provides thickness, stability, and impact resistance. | 60-70% (Total Paper) |

| Core Resin | Phenolic Resin | Saturates the kraft paper, providing strength and heat resistance. | 30-40% (Total Resin) |

| Surface Layer | Decorative Paper | Provides the visual aesthetic (color, pattern). | Included in Paper % |

| Surface Resin | Melamine Resin | Saturates the decorative paper, providing hardness and resistance to scratch, wear, and chemicals. | Included in Resin % |

| Overlay (Optional) | Transparent Paper | A clear top layer saturated with melamine resin, for maximum abrasion resistance. | Varies |

Health and Safety Considerations for HPL

For ship interiors, it's also important to consider emissions. I always advise clients to request technical data sheets confirming compliance with standards like E1 or CARB Phase 2 for low formaldehyde emissions, ensuring better air quality in enclosed cabin spaces. Many reputable manufacturers now offer HPL with no-added-formaldehyde (NAF) resins. Because the resins are fully cured (cross-linked) in the final product, the laminate is inert and stable, so it won't off-gas harmful chemicals over time.

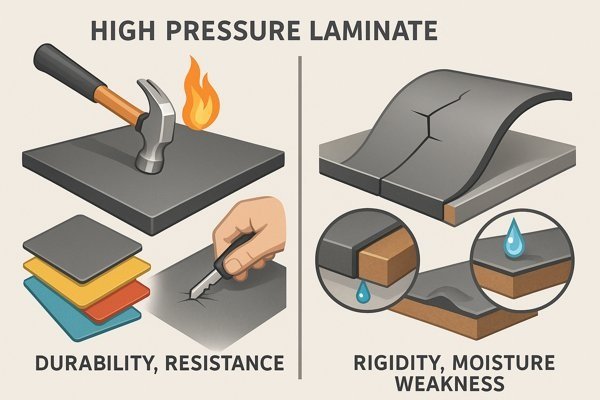

What are the main advantages and disadvantages of HPL?

Choosing a material always involves trade-offs. You need the full picture—the good and the bad—to avoid costly mistakes and ensure you're making the best decision for your project's specific needs.

The main advantages of HPL are its exceptional durability, resistance to scratches, impact, and heat, and its wide range of decorative options. Its primary disadvantages are its rigidity, which limits design on curved surfaces, and the potential for moisture to damage the substrate if edges are not perfectly sealed.

I always present a balanced view to my clients. HPL is a fantastic problem-solver, but knowing its limitations is key to a successful, long-lasting installation.

A Side-by-Side Look at HPL's Pros and Cons

| Advantages | Disadvantages |

|---|---|

| Extreme Durability: Highly resistant to scratches, impact, heat, and stains. | Rigidity: Standard grade cannot be bent; requires special post-forming grade for curves. |

| Low Maintenance: Non-porous surface is hygienic and very easy to clean. | Substrate Vulnerability: The core material can be damaged by water if edges are not perfectly sealed. |

| Design Versatility: Huge range of consistent colors, patterns, and textures. | Difficult to Repair: Deep scratches or chips are hard to repair invisibly; often requires panel replacement. |

| Cost-Effective: Provides a high-end look and robust performance at an affordable price point. | Can Feel "Hard" or "Cold": Lacks the natural softness and warmth of real wood. |

How to Overcome HPL's Disadvantages

The key takeaway is that the disadvantages of HPL can be managed with proper planning. For curved surfaces, you must specify a "post-forming grade" of HPL. To prevent moisture damage, you must insist on high-quality fabrication with waterproof edge sealing. By taking these steps, you effectively neutralize the main risks.

Is High Pressure Laminate durable?

When you're outfitting a vessel that will be at sea for months, "durable" isn't just a buzzword; it's a critical requirement. You need assurance that the materials won't fail under constant use and challenging conditions.

Yes, High Pressure Laminate is exceptionally durable. Its dense, thermoset composition provides superior resistance to impact, abrasion, and general wear and tear, as defined by rigorous international testing standards.

The durability of HPL isn't just a claim; it's a quantifiable result of its engineering.

The Science Behind HPL's Strength

The key to HPL's durability lies in the combination of phenolic and melamine thermosetting resins. When these resins are cured, they form strong, cross-linked molecular bonds, creating a solid, stable material that is far stronger than its paper and resin components.

How Durability is Measured with NEMA Standards

I always refer my clients to the NEMA LD 33 (National Electrical Manufacturers Association) standards, which are the benchmark for laminate performance. These tests simulate real-world wear and tear to guarantee performance.

HPL Performance on Key NEMA Tests

| Test Name | What It Measures | Typical HPL Performance |

|---|---|---|

| Wear Resistance | Resistance to surface abrasion (scuffing and scraping). | Withstands at least 400 wear cycles without damage. |

| Ball Impact Resistance | Ability to resist cracking from a heavy, dropped object. | Withstands a 1-lb steel ball dropped from over 40 inches. |

| Radiant Heat Resistance | Resistance to blistering or delamination from high heat. | Withstands 275°F (135°C) for extended periods. |

Is HPL scratch-resistant?

In a high-traffic environment, surfaces are constantly under assault from keys, tools, and everyday items. You need a material that can resist this daily abuse without looking worn out in a few months.

Yes, HPL is highly scratch-resistant. The top layer of melamine resin is one of the hardest thermosetting plastics used in decorative surfaces, providing excellent protection against scratches from daily use.

While HPL is inherently tough, the choice of finish can affect how visible minor scratches become. This is a practical detail I always discuss with designers.

Why Surface Finish Matters for Scratch Visibility

High-gloss finishes look sleek but will show fine scratches and fingerprints more easily, so I recommend them for vertical applications like wall panels. Matte and textured finishes are much more forgiving. Their low-sheen surfaces break up light and help hide minor wear and tear, making them the ideal choice for hardworking horizontal surfaces like tables and countertops.

Choosing the Right HPL Finish for Your Application

| Finish Type | Description | Scratch Visibility | Best Application |

|---|---|---|---|

| High-Gloss | Shiny, reflective surface. | High. Shows fine scratches and fingerprints easily. | Vertical surfaces, low-traffic areas, decorative accents. |

| Matte / Satin | Low-sheen, non-reflective. | Low. Hides minor scuffs and wear very well. | Horizontal surfaces, countertops, tables, high-traffic areas. |

| Textured | Has a physical texture (like wood grain or stone). | Very Low. The texture breaks up light and conceals daily wear. | The most forgiving option for any high-use application. |

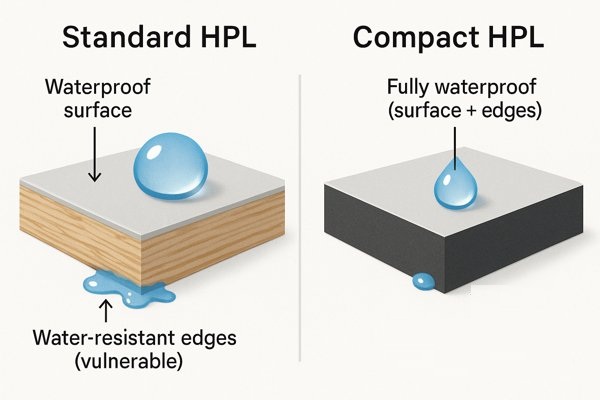

Is HPL waterproof or water-resistant?

Moisture is a constant enemy in the marine industry. From spills in the galley to the humid sea air, you need materials that won't swell, warp, or degrade when they get wet.

The surface of High Pressure Laminate is waterproof. However, a standard HPL panel is considered water-resistant because the wood-based substrate can be damaged if water penetrates the edges. For fully waterproof applications, Compact HPL must be used.

This is the most critical distinction for marine interiors. Using the right product in the right place is key to avoiding costly failures.

The Vulnerability of Standard HPL Panels

The HPL surface itself is non-porous and will not absorb water. The problem is the panel's core, which is typically made of MDF or particleboard. These wood-based materials will act like a sponge if water reaches them through an unsealed edge, causing them to swell and fall apart. Proper edge sealing is therefore essential.

The Ultimate Solution for Wet Areas: Compact HPL

For areas with constant water exposure like shower stalls, the only answer is Compact HPL, also known as Solid Phenolic. It has no wood core and is made of solid resin-impregnated paper, making it completely impervious to water. While more expensive, it is a necessary investment for these critical areas.

Comparing Standard HPL Panels vs. Compact HPL

| Feature | Standard HPL Panel | Compact HPL (Solid Phenolic) |

|---|---|---|

| Core Material | Wood-based (MDF, Particleboard, Plywood) | Solid Phenolic Resin and Kraft Paper |

| Water Resistance | Water-Resistant. Core is vulnerable to moisture. | Fully Waterproof. Core is impervious to water. |

| Edge Sealing | Required. Must be perfectly sealed to prevent water ingress. | Not Required for water protection. |

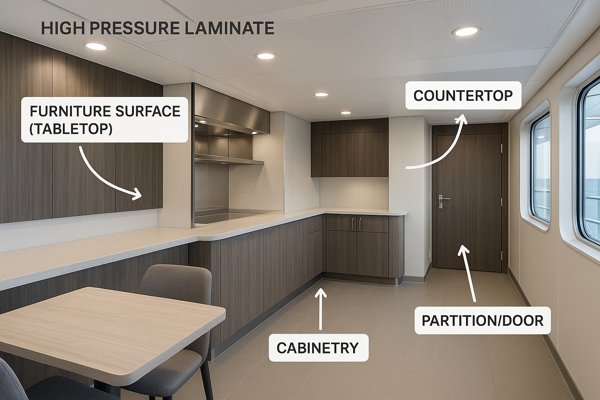

What are high pressure laminates used for?

You're looking for a versatile material that can be used across different areas of a ship. Using one reliable material can simplify purchasing, reduce waste, and ensure a consistent look and quality.

High pressure laminates are used for a wide variety of vertical and horizontal interior surfaces, including furniture, countertops, wall panels, cabinetry, doors, and partitions in high-traffic commercial settings like ships.

On a ship, HPL must be more than just tough; it must also be safe.

Meeting IMO Fire Safety Standards with HPL

Marine-grade HPL must meet strict fire safety standards set by the International Maritime Organization (IMO). When sourcing HPL, you must ensure the product has an IMO FTP Code certification (Wheelmark). This means it has been tested for low flame spread (Part 5) and low smoke and toxicity (Part 2), which are critical for safety in enclosed spaces.

A Guide to HPL Use in Marine Applications

| Application | Key HPL Benefits | Recommended HPL Type |

|---|---|---|

| Cabin Furniture (Desks, Wardrobes) | Durability, Scratch Resistance, Low Maintenance | Standard HPL on MDF or Plywood |

| Mess Room Tables | Impact Resistance, Stain Resistance, Easy to Clean | Standard HPL (Textured Finish) |

| Bulkhead (Wall) Panels | IMO Fire Certification, Durability, Design Consistency | IMO-Certified HPL on a non-combustible or FR core |

| Galley Countertops | Hygienic (NSF Certified), Heat & Stain Resistance | Post-forming HPL on MR MDF |

| Interior Doors | Impact & Scratch Resistance, Easy to Clean | Standard or IMO-Certified HPL |

| Toilet/Shower Partitions | 100% Waterproof, High Durability, Hygienic | Compact HPL (Solid Phenolic) |

Is HPL good for kitchen countertops?

The galley is the heart of a ship's living quarters, and its countertops take a beating. You need a surface that is hygienic, easy to clean, and resistant to heat, stains, and impact from daily food preparation.

Yes, HPL is an excellent and widely used material for kitchen countertops. It offers a durable, non-porous, and hygienic surface that is resistant to stains and moderate heat, all at an affordable price point.

For ship galleys, HPL countertops are the industry standard for good reason. They are hygienic, easy to clean, and tough enough for a commercial environment.

The Advantage of Post-Forming for Seamless Countertops

A key feature of HPL is that special "post-forming" grades are available. This allows a fabricator to heat and bend the laminate in a single sheet to create a rounded front edge and an integrated backsplash. This seamless construction eliminates the corners and seams where dirt and moisture typically collect. This makes the entire work surface easier to clean, more hygienic, and more water-resistant. For any galley project, I always specify post-formed HPL countertops.

Is HPL the same as plastic laminate?

You hear different terms being thrown around—plastic laminate, laminate, Formica, HPL. It can be confusing, and you need to be sure you're specifying and purchasing the right product for your needs.

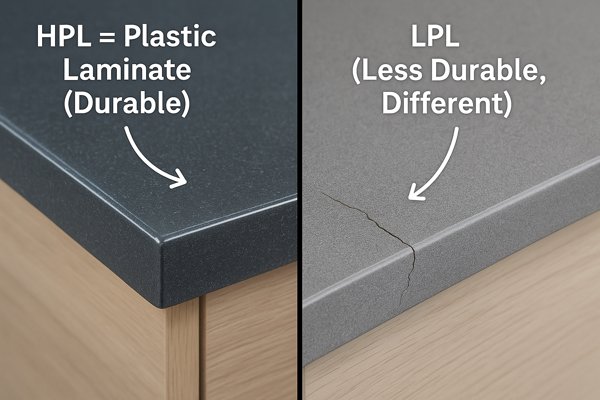

Yes, High Pressure Laminate (HPL) is the technical name for what is commonly called "plastic laminate." The key is not to confuse it with Low Pressure Laminate (LPL), which is a different, less durable product.

This is a critical point of clarification. I've seen projects where a supplier has quoted LPL to win a bid, and the material failed within two years because it wasn't designed for the application. The difference in performance is significant.

Comparing High Pressure vs. Low Pressure Laminate

| Feature | High Pressure Laminate (HPL) | Low Pressure Laminate (LPL) / Melamine |

|---|---|---|

| Pressure | 1,000 - 1,400 PSI | 300 - 500 PSI |

| Structure | Multiple kraft paper layers + decorative layer | Single decorative paper layer |

| Impact Resistance | Very High | Low to Moderate |

| Best Use | Countertops, tables, doors, high-traffic areas. | Vertical surfaces, cabinet interiors, low-traffic areas. |

Always specifying "High Pressure Laminate (HPL) compliant with NEMA LD 3 standards" on your purchase orders is the best way to protect your investment.

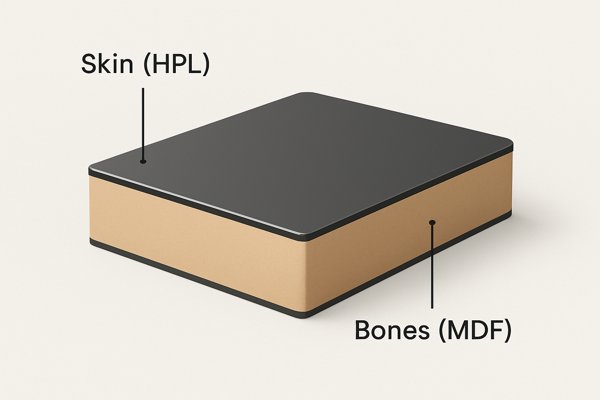

Is HPL better than MDF board?

You're comparing materials and see HPL and MDF mentioned, sometimes together. It's confusing. You need to know if they are competitors or if they work together, and which one to choose for your furniture and paneling needs.

HPL and MDF are not competing products; they are partners. HPL is the thin, durable surface layer (the "skin"), while MDF is a thick, stable core material (the "bones"). They are used together to create a strong, finished panel.

Choosing the right core material for your HPL is just as important as choosing the right decorative finish, especially in a marine environment.

A Guide to Substrate Options for HPL in Marine Environments

| Substrate Type | Key Properties | Best Marine Application | Relative Cost |

|---|---|---|---|

| Standard MDF | Smooth, stable, economical. | Dry interiors: Cabin furniture, closets, decorative panels. | $ |

| Moisture-Resistant (MR) MDF | Treated to resist swelling from humidity and moisture. | Damp areas: Galley cabinets, laundry rooms, public area furniture. | $$ |

| Fire-Retardant (FR) Board | Treated to inhibit combustion and smoke production. | Bulkheads, corridors, and doors where IMO certification is required. | $$$ |

| Marine-Grade Plywood | Excellent strength, superior moisture resistance. | High-end joinery, areas requiring screw-holding strength, high-humidity zones. | $$$$ |

Is HPL better than wood veneer?

You want the warm, classic look of wood, but you're worried about the cost and durability in a tough marine environment. You're considering HPL with a wood grain pattern, but you wonder if it's a good substitute for the real thing.

HPL is a more practical and durable choice than wood veneer for most marine applications. It offers superior resistance to damage and requires far less maintenance, though wood veneer provides an unmatched authentic look and feel.

This is a classic debate of practicality versus authenticity. For the demanding environment of a ship, practicality usually wins.

Comparing HPL vs. Wood Veneer

| Feature | High Pressure Laminate (HPL) | Wood Veneer | Winner for Marine Use |

|---|---|---|---|

| Durability | Extremely high. Resistant to scratches, impacts, stains, and heat. | Moderate. Softer surface can dent and scratch easily. | HPL |

| Maintenance | Very low. Wipes clean with a damp cloth. | Higher. Can need refinishing. Vulnerable to harsh cleaners. | HPL |

| Repairability | Difficult to repair invisibly. Usually requires replacement. | Minor scratches or damage can sometimes be sanded and refinished. | Wood Veneer |

| Cost | More affordable. | More expensive, especially for exotic wood species. | HPL |

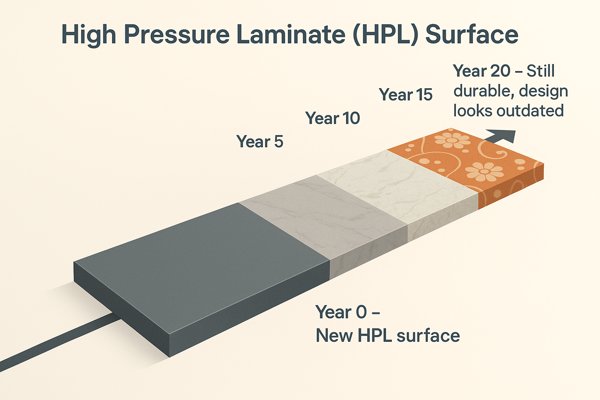

What is the lifespan of HPL?

Investing in an interior outfitting project is a major expense. You need to know how long the materials will last to calculate the true return on investment and avoid frequent, costly replacements.

With proper fabrication and normal use, high-quality High Pressure Laminate surfaces can easily have a lifespan of 15 to 20 years. The durability is so high that the aesthetic design often becomes dated before the material itself fails.

The service life of HPL depends on a few key factors. Managing these correctly is the best way to ensure you get the maximum value from your investment.

A Guide to Maximizing HPL Lifespan

| Influencing Factor | Impact on Lifespan | Best Practice |

|---|---|---|

| Material Quality | Low-quality HPL can wear or delaminate prematurely. | Specify HPL from reputable manufacturers that meet NEMA LD 3 standards. |

| Fabrication | Poorly sealed edges are the #1 cause of failure via moisture damage. | Insist on high-quality edge banding applied with waterproof PUR adhesive. |

| Application | Horizontal surfaces (tables) wear faster than vertical surfaces (walls). | Choose textured finishes and enhanced wear-resistant HPL for high-use horizontal areas. |

| Maintenance | Abrasive cleaners and harsh chemicals will dull the finish over time. | Clean with a soft cloth and mild soap/water. Follow manufacturer guidelines. |

How much does HPL cost per square foot?

Budget is always a major constraint. You need clear, specific cost information to determine if HPL fits within your financial plan and to compare it accurately with other material options.

A standard HPL sheet costs between $1.50 to $5.00 per square foot. The final installed cost of a finished panel or countertop typically ranges from $15 to $40 per square foot, accounting for the substrate, labor, and project complexity.

The total cost is a sum of its parts. For large projects, volume purchasing can reduce material costs by 20-30%. Always get detailed quotes from multiple fabricators that specify the exact HPL product and substrate to ensure you are comparing apples to apples.

Estimating HPL Project Costs (per square foot)

| Cost Component | Low End (Simple/Standard) | High End (Complex/Premium) |

|---|---|---|

| HPL Sheet | $1.50 (Standard Solid Color) | $5.00+ (Premium Textured/IMO-Cert) |

| Substrate | $1.00 (Standard Particleboard) | $5.00+ (FR Plywood) |

| Fabrication & Labor | $10.00 (Simple flat panels) | $30.00+ (Post-formed countertops) |

| Estimated Total | ~$12.50 | ~$40.00+ |

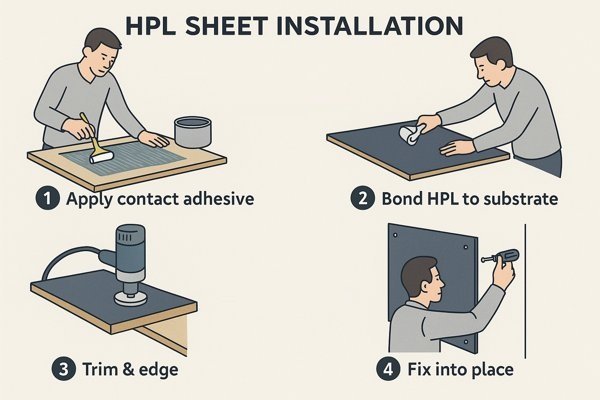

How are HPL sheets installed?

You've selected HPL, but the project isn't finished until it's properly installed. Understanding the process helps you manage timelines, coordinate with contractors, and ensure the final result is durable and looks professional.

HPL sheets are installed by bonding them to a suitable substrate using a contact adhesive. The finished panel is then cut, edged, and mechanically fastened or glued into place. Precision and proper technique are essential for a long-lasting result.

A high-quality material can be ruined by poor installation. I have seen it happen, and the most common mistakes are almost always preventable.

Avoiding Common HPL Installation Failures

Poorly sealed edges exposed to moisture are the number one cause of failure I see in marine environments. It's a critical detail that must be done right. Here are other common problems and how to prevent them:

A Troubleshooting Guide for HPL Installation

| Problem | Common Cause | Solution / Prevention |

|---|---|---|

| Bubbles or Delamination | Insufficient adhesive; improper pressure; trapped dust/debris. | Ensure 100% adhesive coverage. Use a J-roller for firm pressure. Work in a clean environment. |

| Warped Panels | Failure to acclimatize materials; bonding HPL to only one side of a substrate. | Acclimatize HPL and substrate for 48+ hours. Use a backer laminate on the reverse side for balanced construction. |

| Cracked/Chipped Edges | Using the wrong saw blade; dull tooling. | Use a sharp, triple-chip grind carbide blade designed for laminates. Cut into the decorative face. |

| Swollen Core Material | Poorly sealed edges exposed to moisture. | This is the most critical failure. Insist on high-quality, waterproof edge banding (e.g., PVC/ABS with PUR glue). |

Proper installation is the final, crucial step. I always recommend using fabricators with proven experience in marine interior outfitting to guarantee the performance you expect from HPL.

Conclusion

In short, High Pressure Laminate is a versatile, durable, and cost-effective material. When properly specified, fabricated, and installed, it offers unmatched performance and design flexibility for demanding marine interior applications.

-

Explore this link to understand the significance of phenolic resin in creating durable materials. ↩

-

Discover how melamine resin enhances the durability and aesthetics of surfaces in this informative resource. ↩

-

Explore this link to understand the NEMA LD 3 standards, which ensure laminate durability and performance in real-world conditions. ↩