Struggling with weight calculations for your marine project? Choosing the right wall panel is crucial, but the numbers can be confusing. The wrong choice can impact fuel efficiency, stability, and overall vessel performance.

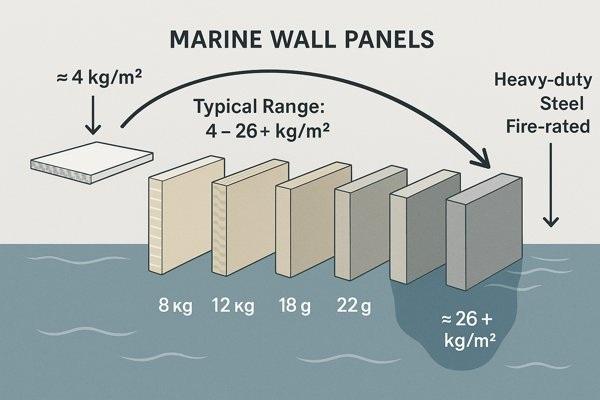

The typical weight of marine wall panels ranges from approximately 4 kg/m² for the lightest composite panels to over 26 kg/m² for heavy-duty, fire-rated steel panels. The final weight depends on the core material, thickness, surface finish, and required fire rating.

This article will break down everything you need to know about marine wall panel weights. I'll share insights from my years as a marine interior outfitting specialist to help you make informed decisions for your projects. We'll explore the key factors that influence panel weight, from fire ratings to acoustic properties, and I'll show you exactly how to calculate the total weight you'll need.

What Factors Determine The Weight Of A Marine Wall Panel?

Ever wonder why two seemingly similar wall panels have vastly different weights? The secret lies in their composition. Understanding these differences is key to managing your vessel's weight budget and ensuring optimal performance.

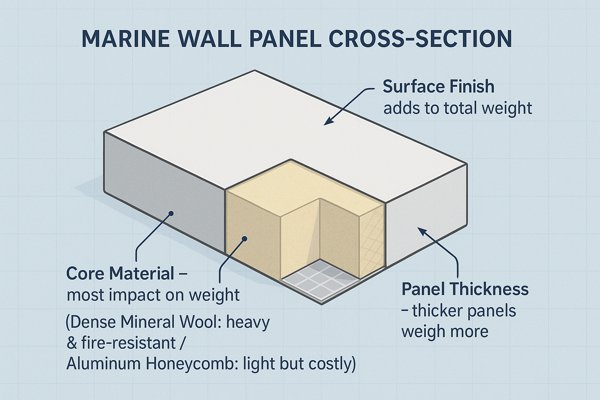

A panel's weight is determined by its core material, thickness, and surface finish. Focus first on the core material, as it has the largest impact; dense mineral wool is heavy but fire-resistant, while aluminum honeycomb is extremely light but comes at a premium price.

Let's dive deeper into these elements. From my experience, the core material is the biggest player. A panel with an aluminum honeycomb core will be significantly lighter than one with a mineral wool core designed for high fire resistance. But there's more to it than just the core. The type of adhesive used to bond the layers and the density of the surface laminate also contribute to the final tally. I remember a project where we had to choose between two panels with the same core, but one used a lighter, more advanced bonding agent that saved us almost 0.5 kg/m². On a large cruise ship, that small difference can add up to several tonnes.

Key Components That Determine Panel Weight

A marine wall panel is a composite system where every layer counts.

- Core Materials: This is the heart of the panel and the primary driver of its properties.

- Mineral Wool: Excellent for fire and sound insulation. Densities typically range from 80 kg/m³ for standard panels up to 180 kg/m³ for high-performance acoustic or A-60 rated panels.

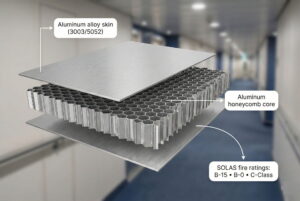

- Aluminum Honeycomb: The champion of lightweight construction. It offers a fantastic strength-to-weight ratio but is one of the most expensive options.

- Polyurethane (PU) Foam: Good thermal insulation and very light, but generally only used for C-class divisions due to its combustible nature.

- Surface Finishes (Facings): These provide the decorative look and durability.

- PVC Film: Very light, typically adding less than 0.5 kg/m².

- High-Pressure Laminate (HPL)1: More durable and scratch-resistant, but also heavier, adding 1-1.5 kg/m² per side.

- Galvanized Steel Sheet: The heaviest option, used for A-class panels. A 0.7mm thick steel sheet adds about 5.5 kg/m².

- Adhesives: The unseen contributor to weight. A two-part polyurethane adhesive is common, but its application rate can vary. A thicker adhesive layer adds weight but can improve bond strength and acoustic damping.

Here's a quick comparison to guide your decision-making:

| Core Material | Typical Weight Range (kg/m²) | Fire Resistance | Acoustic Performance | Relative Cost |

|---|---|---|---|---|

| PU Foam | 4 - 8 | Low (C-Class) | Poor | Low |

| Mineral Wool | 19 - 24 (B-15) | Excellent | Good to Excellent | Medium |

| Aluminum Honeycomb | 6 - 8 (B-15) | Good | Fair | Very High |

How Does A Panel's Fire Rating Affect Its Weight Per Square Meter?

Concerned about meeting stringent fire safety regulations without adding excessive weight? The fire rating of a panel is a critical factor, but it often comes with a weight penalty. Navigating this trade-off is a common challenge in marine outfitting.

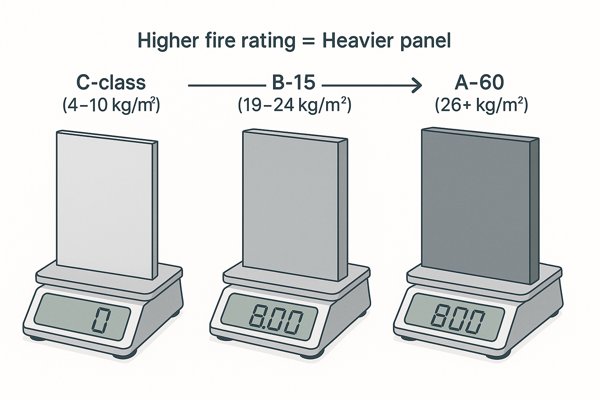

A panel's fire rating directly increases its weight. For example, a basic C-class panel might weigh 4-10 kg/m², while a SOLAS-compliant B-15 rated panel jumps to 19-24 kg/m², and a heavy-duty A-60 panel can exceed 26 kg/m² due to denser core materials.

The reason for this dramatic weight increase lies in the IMO Fire Test Procedures (FTP) Code2. A panel has to prove it can maintain both "Integrity" and "Insulation." Integrity means it won't allow flames or hot gasses to pass through for a set time (e.g., 60 minutes for A-60). Insulation means the temperature on the non-fire side won't rise above a certain limit (140°C average). To achieve this, you need mass and density. I've seen tests where a panel maintained its integrity but failed on insulation because the core material wasn't dense enough to stop the heat transfer. That's why A-60 panels require very dense mineral wool and steel facings on both sides, which are the primary contributors to their high weight.

Understanding Fire Classifications and Their Impact on Weight

To make the requirements clearer, here is a breakdown of the performance criteria for common fire ratings:

| Fire Rating | Base Material | Integrity Time (Minutes) | Insulation Time (Minutes) |

|---|---|---|---|

| B-15 | Non-combustible | 30 | 15 |

| A-0 | Steel or Equiv. | 60 | 0 |

| A-15 | Steel or Equiv. | 60 | 15 |

| A-60 | Steel or Equiv. | 60 | 60 |

Understanding these nuances is key. You might be able to use a lighter A-0 panel instead of an A-15 in some areas, saving weight while remaining fully compliant. Always consult the vessel's fire plan to know exactly what is required.

What Is The Relationship Between Marine Panel Thickness And Its Overall Weight?

Is a thicker panel always a heavier panel? It seems logical, but the relationship isn't always that straightforward. The material composition plays a significant role, and understanding this can help you optimize your material selection.

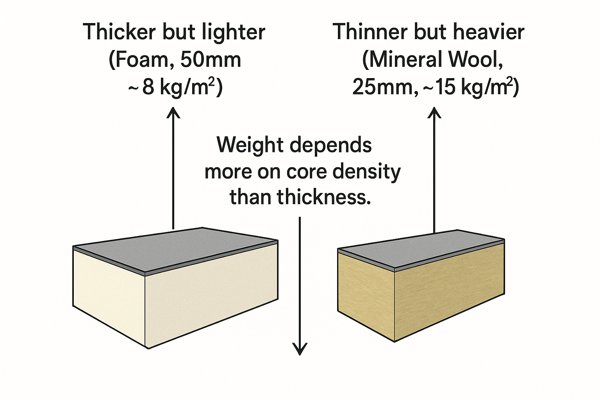

Weight increases with thickness, but the core material is more critical. For instance, a 50mm thick lightweight foam panel (around 8 kg/m²) can be significantly lighter than a thinner 25mm mineral wool panel (around 15 kg/m²). Always compare material densities, not just thickness.

Beyond weight, you must consider "functional thickness." The thickness of a panel is often dictated by practical needs. A standard 50mm thick panel is widely used because it provides a sufficient cavity to run electrical conduits and small pipes. A 25mm panel, while lighter, offers very little space for these services. I always advise clients to coordinate with their electrical and plumbing teams before finalizing panel thickness.

Choosing a Panel Thickness: A Trade-Off Analysis

Choosing the right thickness involves balancing multiple factors, as shown in the table below.

| Thickness | Typical Use | Pros | Cons |

|---|---|---|---|

| 25mm | Linings, weight-sensitive areas | Lighter weight, saves space | Poor acoustic performance, no room for services |

| 50mm | Standard cabin walls, wet units | Good balance of weight, acoustics, services space | Heavier than 25mm, can be oversized for linings |

| 75mm+ | High acoustic areas, machinery space boundaries | Excellent acoustic performance, large service cavity | Heavy, reduces usable cabin space |

Sometimes, a thicker but lower-density panel is the best solution. Imagine you need a certain level of acoustic performance. A 50mm panel with a standard density core might provide better acoustic performance than a 25mm panel with a very dense core, and it might not be significantly heavier. You're getting more functionality for a manageable weight increase.

How Much Weight Do Joint Profiles And Installation Hardware Add To A Wall System?

Focusing solely on the panel weight can be a mistake. The joining profiles and installation hardware, though small individually, can add up. Ignoring them can lead to inaccurate weight calculations and potential issues down the line.

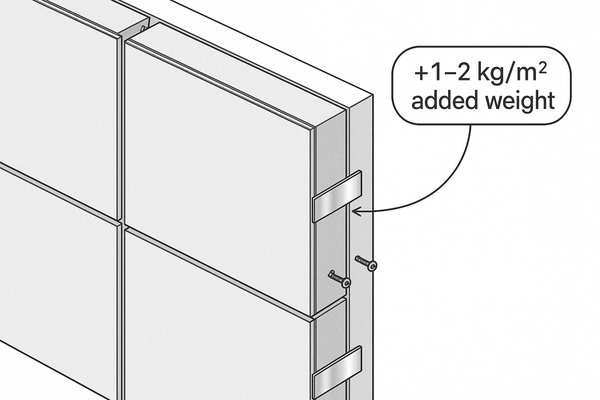

Joint profiles and installation hardware will add approximately 1 to 2 kg/m² to the total weight of your wall system. For accurate project estimates, always add this extra weight to the panel's specified weight per square meter.

The material of the profiles themselves is a major variable. For most B-15 systems, extruded aluminum profiles are standard. However, when you are constructing an A-60 bulkhead, the joint must also maintain that rating, which often requires heavier steel profiles. I worked on a galley project where the switch from aluminum to steel profiles added nearly 1.5 kg/m² extra to the system weight.

Here’s a direct comparison of the two most common profile materials:

| Property | Aluminum Profiles | Steel Profiles |

|---|---|---|

| Weight | Lightweight | Heavy (3x heavier than aluminum) |

| Cost | Moderate | Low to Moderate |

| Corrosion Resistance | Excellent | Good (when galvanized/painted) |

| Required For | B-Class Systems, C-Class | A-Class Systems |

Analyzing the Weight of Installation Components

- Profiles: Aluminum (lightweight) vs. Steel (heavy, for A-Class).

- Fasteners: The number and type of screws add up.

- Specialized Hardware: If you're installing a "floating" wall system for high acoustic performance, the anti-vibration mounts and brackets add another layer of weight. These specialized rubber and steel mounts are essential for performance but must be included in your weight budget.

Always request the weight per linear meter for all profiles from your supplier and factor it into your calculations based on the cabin layout.

What Are The Lightest Solas-Compliant Wall Panels Available?

Searching for the ultimate in lightweight construction without compromising on safety? The demand for lighter, SOLAS-compliant panels is driving innovation in the industry. Knowing your options can give you a significant competitive edge.

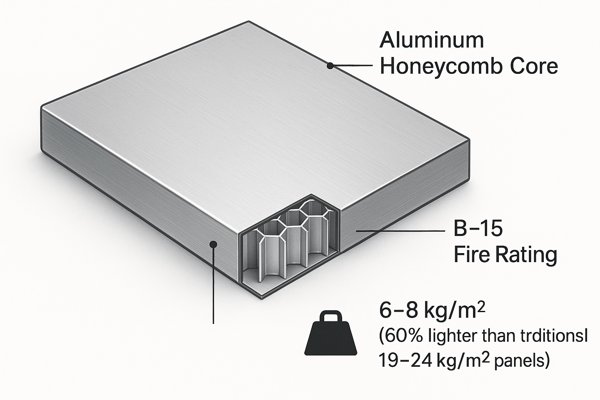

The lightest SOLAS-compliant panels use an aluminum honeycomb core to achieve a B-15 fire rating at a weight of only 6 to 8 kg/m². This offers a direct weight saving of over 60% compared to traditional 19-24 kg/m² mineral wool B-15 panels.

While aluminum honeycomb is the market leader, other advanced materials are also available for specialized applications on high-speed ferries, naval vessels, and performance yachts. The facings on these panels are also optimized. Instead of standard steel, they might use thin aluminum sheets or even composite materials like fiberglass or carbon fiber for the ultimate in weight reduction, though this comes with a very high cost.

A Comparison of Advanced Lightweight Panel Materials

| Core Material | Facing Material | Typical B-15 Weight (kg/m²) | Key Advantage |

|---|---|---|---|

| Aluminum Honeycomb | Aluminum/Fiberglass | 6 - 8 | Best strength-to-weight ratio; widely used. |

| Phenolic Foam | Fiberglass/HPL | 8 - 12 | Excellent fire properties (low smoke/toxicity). |

| End-grain Balsa Wood | Fiberglass | 9 - 14 | Natural, sustainable, good stiffness. |

| Carbon Fiber Composite | Carbon Fiber | 4 - 6 | Ultimate lightness and strength; very high cost. |

When I work with clients designing fast craft, we often create a detailed weight-cost analysis. An aluminum honeycomb panel might cost three times more than a mineral wool panel, but the lifetime fuel savings can justify the initial investment.

Is There A Correlation Between The Weight Of A Panel And Its Acoustic Insulation Rating?

Trying to create a quiet and comfortable environment onboard? Acoustic insulation is key, but does it have to come at the cost of added weight? The relationship between a panel's weight and its soundproofing capabilities is more complex than you might think.

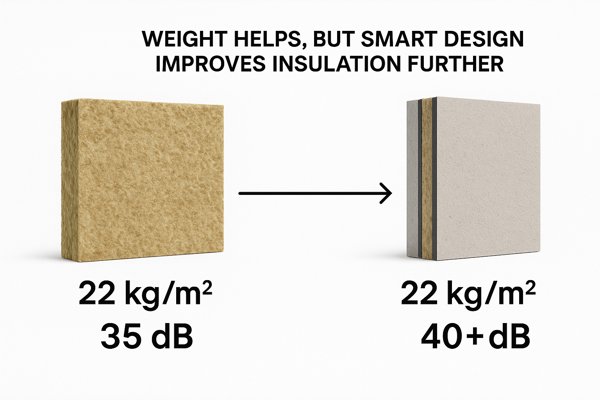

Yes, weight and sound reduction are linked, but smart design is key. A standard 22 kg/m² mineral wool panel might offer a 35 dB rating, but a specialized acoustic panel can exceed 40 dB at a similar weight by using advanced damping layers.

The basic principle in acoustics is the "Mass Law3," which states that if you double the mass (weight) of a partition, you increase its sound insulation by about 6 decibels (dB). However, modern acoustic panels "cheat" the mass law by using constrained layer damping, converting sound vibration into heat. This allows for excellent performance without excessive weight.

The Science of Sound Insulation: Mass Law vs. Damping

To help translate the technical ratings into real-world experience, here's what you can expect at different levels of sound insulation:

| Sound Reduction (Rw) | Subjective Experience | Typical Application |

|---|---|---|

| 30-35 dB | Normal speech can be heard and understood. | Standard cabin divisions |

| 36-42 dB | Loud speech is audible as a murmur but not intelligible. | Upgraded / quiet cabins |

| 43-50 dB | Loud speech is not audible. | Luxury cabins, meeting rooms |

| 50+ dB | Very loud sounds (e.g., stereo) are barely audible. | Adjacent to noisy public areas or machinery spaces. |

For the highest levels (50+ dB), a single panel is not enough. You need system-level solutions like double walls and floating floors to isolate the cabin from the ship's structure.

How To Calculate The Total Weight Of Wall Panels Needed For A Ship's Cabin?

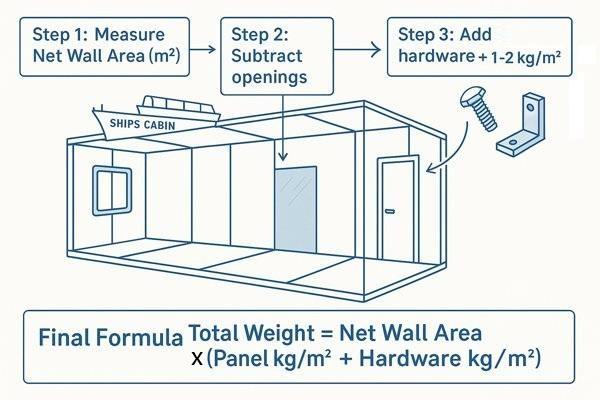

Ready to put all this knowledge into practice? Accurately calculating the total weight of the wall panels for a cabin is a critical step in the design and procurement process. It's a straightforward calculation, but it requires careful attention to detail.

Use this formula for a quick estimate: Total Weight = Net Wall Area (m²) x (Panel kg/m² + Hardware kg/m²). First, calculate the wall area, subtract openings like doors, then add 1-2 kg/m² for hardware to get an accurate total.

I always use a simple spreadsheet to do these calculations. The table below can serve as a template for your own calculations.

A Step-by-Step Calculation Worksheet

Let's use our example cabin: 3m long, 4m wide, 2.4m high, with one door (0.8m x 2m) and one window (1m x 0.8m).

| Calculation Step | Item Description | Value / Formula | Result (m² or kg) |

|---|---|---|---|

| 1. Gross Wall Area | Long Walls | 2 x (3m x 2.4m) | 14.4 m² |

| Short Walls | 2 x (4m x 2.4m) | 19.2 m² | |

| 2. Subtract Openings | Door Area | 0.8m x 2m | -1.6 m² |

| Window Area | 1m x 0.8m | -0.8 m² | |

| A. Net Wall Area | (Sum of above) | (14.4+19.2) - (1.6+0.8) | 31.2 m² |

| 3. Panel Weight Calc. | Panel Weight (e.g., B-15) | 22 kg/m² | |

| B. Total Panel Weight | Net Area x Panel Weight | 31.2 m² x 22 kg/m² | 686.4 kg |

| 4. Hardware Weight Calc. | Hardware Weight (estimate) | 1.5 kg/m² | |

| C. Total Hardware Weight | Net Area x Hardware Weight | 31.2 m² x 1.5 kg/m² | 46.8 kg |

| 5. Final Calculation | Sub-Total Weight (B + C) | 686.4 kg + 46.8 kg | 733.2 kg |

| Contingency Margin (e.g., 5%) | 733.2 kg x 0.05 | 36.7 kg | |

| D. Final Estimated Weight | (Sub-Total + Contingency) | 733.2 kg + 36.7 kg | 769.9 kg |

Creating a Weight Budget

As a best practice, I always advise procurement officers to add a 5-10% contingency to their final weight calculation. Projects evolve, and this margin prevents a small change from causing a major weight problem for the naval architects. It's a simple step that demonstrates professionalism and foresight.

Conclusion

In short, understanding marine wall panel weights is key to a successful project. From core materials to fire ratings, every detail matters for performance, safety, and budget.

-

Discover why HPL is favored for its durability and scratch resistance, and learn how it impacts panel weight and performance in marine environments. ↩

-

Exploring this resource will provide you with a comprehensive understanding of fire safety regulations and their implications. ↩

-

Understanding the Mass Law is crucial for anyone interested in sound insulation, as it lays the foundation for effective acoustic design. ↩