Struggling to choose a wall panel finish that withstands harsh marine conditions? The constant exposure to humidity, salt, and wear can quickly ruin standard materials. You need a solution that is durable, compliant, and looks great.

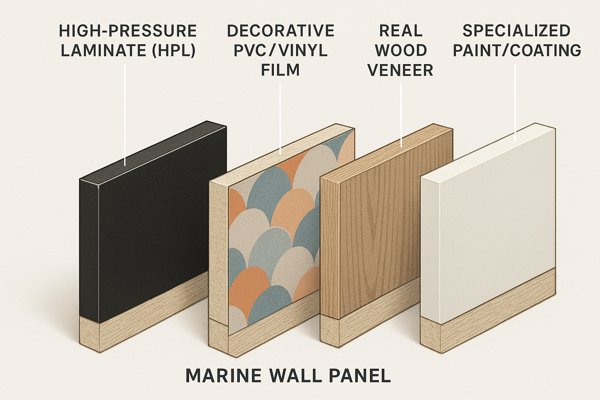

The primary types of surface finishes available for marine wall panels are High-Pressure Laminate (HPL), decorative PVC or vinyl films, real wood veneers, and specialized paint or coating systems. These finishes are chosen for their durability, fire resistance, and aesthetic qualities suitable for the demanding marine environment.

Choosing the right finish for marine wall panels is a critical decision that impacts not just the look and feel of your vessel's interior, but also its safety, durability, and long-term maintenance costs. As a marine interior outfitting specialist, I've helped countless clients navigate this choice, ensuring their selection meets stringent maritime regulations while achieving the desired aesthetic. Let's explore the options in detail to find the perfect fit for your project.

What Are The Main Categories Of Surface Finishes Used On Marine Wall Panels?

Are you feeling overwhelmed by the sheer number of finish options? It's tough to know where to start when each choice seems to have its own set of technical specifications. You need a clear breakdown of the main categories.

The main categories are laminates, films, veneers, and liquid coatings. High-Pressure Laminate (HPL) offers maximum durability. Decorative PVC/vinyl films provide vast design flexibility. Real wood veneers give a classic, luxurious feel. Finally, marine-grade paints and epoxy coatings offer a seamless, protective layer.

Understanding these four fundamental groups is the first step. Each is suited for different applications based on traffic, aesthetics, and budget. I remember a client, a procurement officer, who was stuck between HPL and a PVC film. We broke it down by location: HPL was essential for the high-traffic mess hall and corridors, while the more budget-friendly PVC was perfect for the passenger cabins. The table below summarizes each category.

Category 1: High-Pressure Laminate (HPL)1

| Finish Category | Description | Typical Shipboard Applications |

|---|---|---|

| High-Pressure Laminate (HPL) | A tough, decorative surface made by fusing resin-impregnated paper under high heat and pressure. | Corridors, doors, mess rooms, countertops, public areas. |

Category 2: Decorative PVC/Vinyl Films

| Finish Category | Description | Typical Shipboard Applications |

|---|---|---|

| Decorative PVC/Vinyl Films | Flexible thermoplastic films printed with various patterns and laminated onto a panel. | Cabin walls and ceilings, furniture facings, low-traffic areas. |

Category 3: Real Wood Veneer

| Finish Category | Description | Typical Shipboard Applications |

|---|---|---|

| Real Wood Veneer | Thin slices of actual wood bonded to a panel and sealed with marine-grade lacquers for a luxurious finish. | Officer's lounges, luxury suites, boardrooms, feature walls. |

Category 4: Paints and Protective Coatings

| Finish Category | Description | Typical Shipboard Applications |

|---|---|---|

| Paints & Protective Coatings | High-performance liquid coatings, usually two-part epoxies and polyurethanes, that create a hard, seamless surface. | Galleys, wet units (bathrooms), workshops, storerooms. |

What Specific Properties Define A "Marine-Grade" Surface Finish?

Wondering what makes a standard finish different from a "marine-grade" one? Using the wrong material can lead to costly failures like delamination, fading, and corrosion. You need to know the specific properties to look for.

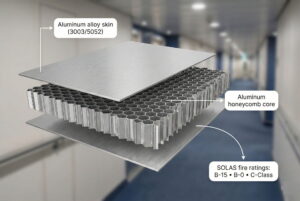

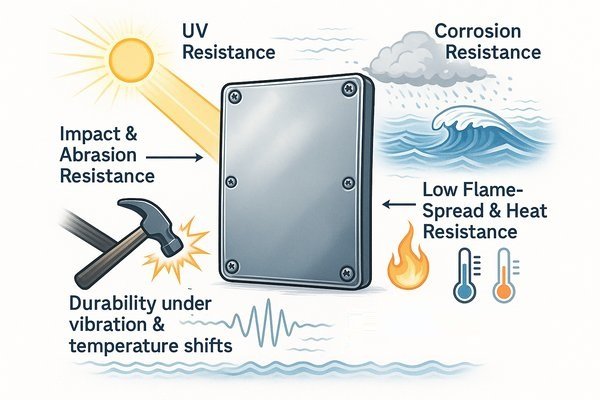

A "marine-grade" surface finish is defined by its superior resistance to moisture, salt spray, UV radiation, and impact. It must also have low flame-spread characteristics, high durability against abrasion, and the ability to withstand the constant vibration and temperature shifts found on a vessel.

The term "marine-grade" guarantees performance in a uniquely challenging environment. It’s not just about water resistance. A ship is a dynamic structure; it flexes, vibrates, and experiences rapid temperature changes. A finish must be robust enough to handle the mechanical stress of a vessel's movement and the thermal shock of moving between a cold, air-conditioned interior and a bulkhead heated by the sun. These properties are verified through standardized testing.

Key Tests That Define a Marine-Grade Finish

A finish must excel in several areas to be considered marine-grade.

| Property | Standard/Test Method | Why It's Critical & Typical Values |

|---|---|---|

| UV Resistance | ASTM G1542 | Sunlight through windows and portholes can rapidly fade and degrade interior finishes. This test simulates weathering to ensure color stability. High-performance finishes show minimal color change (a Delta E value of < 3) after 1000 hours of exposure. |

| Abrasion Resistance | ISO 4586-23 | High traffic from crew, passengers, and equipment wears surfaces down. This test measures wear-through from abrasive wheels. Marine-grade HPL typically requires >400 revolutions to show initial wear. |

| Impact Resistance | ISO 4586-2 | Doors slam and equipment gets bumped against walls, especially in rough seas. This test drops a steel ball to ensure the surface doesn't crack or fracture under significant impact force (e.g., >25 N). |

| Moisture & Salt Spray | ASTM B1174 | The air at sea is humid and corrosive. This test exposes the material to salt spray for 1000+ hours. A marine-grade finish must show no blistering, corrosion, or delamination. |

| Thermal Stability | Internal Manufacturer Tests | A panel might have a cold AC unit on one side and be a hot engine room bulkhead on the other. The finish must not crack or delaminate under this thermal stress, remaining stable across a range like -30°C to +70°C. |

How Are Surface Finishes Tested And Certified For Fire Safety In Marine Applications?

Are you concerned about meeting strict fire safety rules? Non-compliance is not an option, as it can halt a project and lead to severe penalties. You must understand the certification process to ensure your materials are approved.

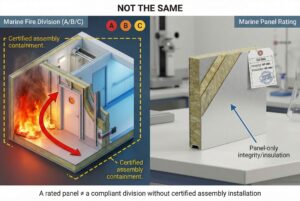

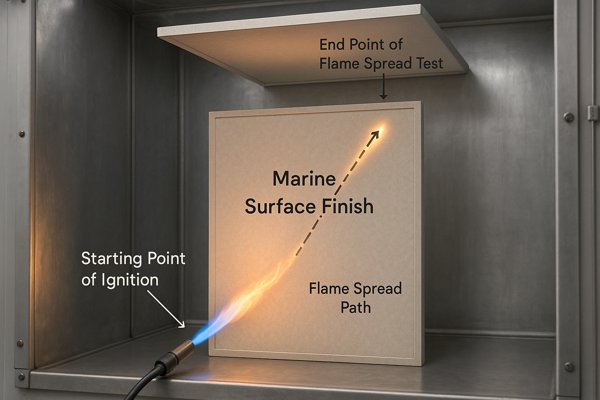

Surface finishes are certified according to the IMO Fire Test Procedures (FTP) Code. The key test is Part 5 (Surface Flammability), which classifies a material as having "Low Flame Spread." This certification is essential for use on bulkheads and ceilings in most areas of a ship.

Fire safety is paramount. The finish itself is only one part of the equation; it is tested as part of a complete panel system. The surface finish is applied to a non-combustible core material, typically mineral wool, which has a very high melting point (>1000°C). This core prevents the fire from burning through the panel. The surface finish's job is to prevent the fire from spreading across the panel. Both components must work together to achieve compliance. The "Wheelmark" (MED certificate) proves this entire system has passed.

Understanding the IMO FTP Code Part 5 Test5 for Surface Flammability

This test exposes a panel sample to a radiant heat panel to see how it contributes to a fire.

| Parameter | Symbol | Simple Explanation | Pass Criteria |

|---|---|---|---|

| Critical Flux at Extinguishment | CFE | How much heat does it take to keep the flame spreading? A higher value is better, meaning the fire gives up easily. | Greater than or equal to 20.0 kW/m² |

| Heat for Sustained Burning | Qsb | How much energy does the material need to absorb before it really starts burning on its own? Higher is better. | Greater than or equal to 1.5 MJ/m² |

| Total Heat Release | Qt | How much fuel does the material add to the fire in total? Lower is better. | Less than or equal to 0.7 MJ |

| Peak Heat Release Rate | qp | How quickly and intensely does the material burn at its worst point? Lower is better. | Less than or equal to 4.0 kW |

What Are The Pros And Cons Of High-Pressure Laminate (HPL) As A Finish For Marine Panels?

Considering HPL for its famous durability? While it's one of the toughest finishes available, its rigidity and cost can be a drawback. You need a balanced view to decide if it's the right choice for your application.

HPL's main pros are exceptional durability, high resistance to scratches, impact, and heat, and easy cleanability. The primary cons are its higher cost compared to films, its rigidity which makes it unsuitable for curved surfaces, and the potential for chipping if improperly handled.

HPL is the champion of high-traffic areas. Its long-term value often outweighs its initial cost. Consider a 100 square meter corridor: a PVC film solution might cost 4,000 USD for the finished panels, while an HPL solution might be 30% more upfront, at 5,200 USD. However, over 10 years, the less durable PVC may require 2,000 USD in repairs, making its total cost higher. The HPL's robustness often makes it the more economical choice in the long run. Here’s a clear breakdown of its advantages and disadvantages.

HPL Performance: A Detailed Breakdown

| Pros of HPL | Cons of HPL |

|---|---|

| Extreme Durability: Superior resistance to abrasion, impact, and scratches. | Higher Initial Cost: Premium price point compared to films and some paints. |

| Hygienic Surface: Non-porous and easy to clean, resisting stains and bacteria. | Rigidity: Cannot be bent to a tight radius, limiting it to flat surfaces. |

| Fire Resistant: Widely available with IMO "Low Flame Spread" certification. | Installation: Requires specialized tools to cut without chipping the edges. |

| Design Versatility: Huge range of colors, patterns, and textures available. | Weight: Adds more weight to the panel assembly than a thin film does. |

How Do Decorative PVC Or Vinyl Films Compare To HPL For Marine Interiors?

Looking for a more cost-effective or flexible design solution? Decorative films offer an incredible variety of finishes, but you might be worried they won't hold up. You need a direct comparison to HPL on the factors that matter most.

Decorative PVC films are more flexible, lightweight, and cost-effective than HPL, offering a wider range of designs for curved surfaces. However, HPL is significantly more durable, offering superior resistance to deep scratches, high impact, and heat, making it better for high-traffic areas.

The choice between PVC film and HPL often comes down to balancing budget, design, and durability. For cabin walls where traffic is low, a high-quality IMO-certified PVC film is an excellent choice. However, for a door or corridor that will be hit by luggage carts, HPL is the only sensible option. The repair aspect is also key. While a PVC patch is possible, it's very difficult to perfectly match the color and pattern of a film that has been in service for years due to slight fading.

PVC Film vs. HPL: A Head-to-Head Comparison

| Feature | Decorative PVC/Vinyl Film | High-Pressure Laminate (HPL) |

|---|---|---|

| Durability | Good resistance to light scratches. Can be punctured by sharp objects. | Excellent resistance to abrasion, deep scratches, impact, and heat. |

| Flexibility | Highly flexible. Can be wrapped around curved edges and complex shapes. | Rigid. Cannot be bent to a tight radius. |

| Cost | More economical. A decorative marine-grade teak vinyl can cost around 4.00 USD/sq ft. | Premium price. The finished panel can be 20-40% more expensive. |

| Weight | Very lightweight. Adds minimal weight to the substrate panel. | Heavier. Adds more weight to the overall panel construction. |

| Repair | Difficult to repair invisibly. Patching often looks obvious due to aging/fading. | Small chips and scratches can be filled with color-matched hard wax kits. |

What Are The Best Practices For Using Real Wood Veneer As A Surface Finish In A Marine Environment?

Do you want the classic, luxurious look of real wood? Using natural wood at sea presents challenges with moisture and sun exposure. You must follow best practices to prevent warping, fading, and delamination.

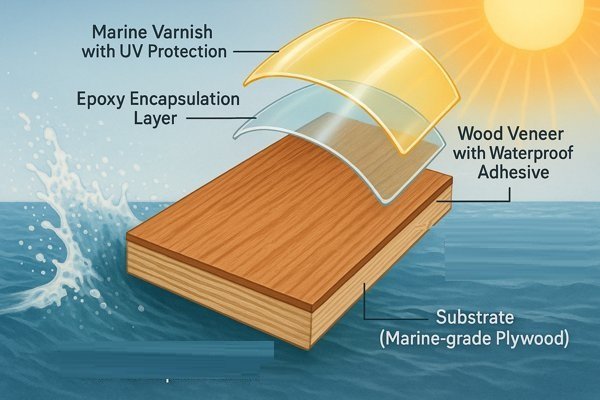

The best practices are to use a marine-grade substrate, fully encapsulate the veneer with epoxy resin, use waterproof adhesives, and apply multiple coats of a marine varnish with UV inhibitors to provide a durable, moisture-proof finish.

The beauty of wood is unmatched, but it requires meticulous preparation. For marine use, a quarter-sawn veneer is often preferred as its straight grain pattern is more dimensionally stable. For even greater stability and consistency, high-quality engineered wood veneers are an excellent modern alternative. They are made from real wood but processed to create a perfect, repeatable grain with no natural defects. The following steps are critical for a long-lasting result.

Best Practices for Marine Wood Veneer Application

| Step | Action | Critical Detail / Rationale |

|---|---|---|

| 1. Selection | Choose a marine-grade plywood substrate (BS 1088) and a stable veneer (quarter-sawn or engineered). | A stable foundation prevents the final panel from warping. |

| 2. Adhesion | Bond the veneer to the substrate using a two-part marine-grade epoxy adhesive under even pressure (e.g., a vacuum press). | Creates a waterproof, permanent bond that will not fail in high humidity. |

| 3. Encapsulation | Coat the entire panel (face, back, and all edges) with 2-3 layers of clear, low-viscosity epoxy resin. | This is the most crucial step. It creates a complete moisture-proof barrier, stabilizing the wood. |

| 4. Finishing | Apply 6-10 coats of a high-quality marine varnish or two-part polyurethane containing strong UV inhibitors. | The multiple coats build a thick, durable, and UV-resistant layer that protects the wood and provides a deep finish. |

What Types Of Paints Or Protective Coatings Are Suitable For Direct Application Onto Marine Wall Panels?

Need a seamless, durable, and easy-to-clean finish for your wall panels? Paint offers great protection, but standard house paint will fail quickly at sea. You must use a coating system designed for marine challenges.

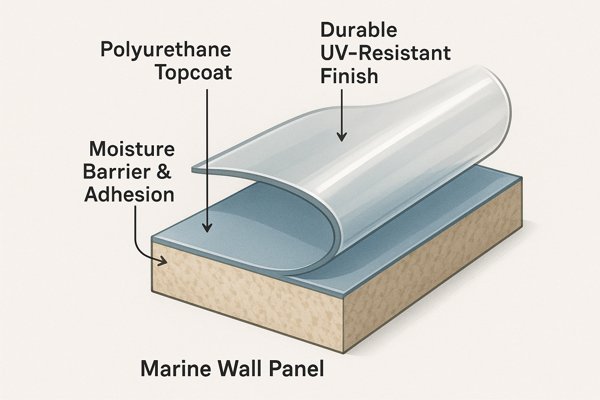

The most suitable paints are two-part (2K) systems, specifically epoxy primers and polyurethane topcoats. Epoxy primers provide excellent adhesion and a moisture barrier, while polyurethane topcoats offer a hard, durable finish with superior UV resistance and gloss retention.

For areas like galleys and wet units, a painted finish is the most practical choice. The application method significantly impacts the final quality. Spray application is preferred for a smooth, "mirror-like" finish that is easiest to clean. It's also important to consider regulations regarding Volatile Organic Compounds (VOCs)6. Modern marine coatings are formulated to have low VOC content to ensure safe air quality in enclosed spaces. The coating system is comprised of two essential layers.

Marine Coating System Breakdown

| Layer | Type | Primary Function | Key Properties | Typical DFT |

|---|---|---|---|---|

| Primer | Two-Part Epoxy | Adhesion & Protection | Creates a tenacious bond to the substrate and forms a waterproof, anti-corrosive barrier. | 120-150 micrometers |

| Topcoat | Two-Part Polyurethane | Durability & Aesthetics | Provides a hard, scratch-resistant finish with excellent UV stability (won't yellow) and color retention. | 50-100 micrometers |

How Does The Type Of Surface Finish Affect The Cleaning And Long-Term Maintenance Of Wall Panels?

Thinking about the future life of the vessel? The finish you choose today will determine the cleaning effort and maintenance costs for years to come. An easy-to-clean surface saves time, money, and keeps the interior looking its best.

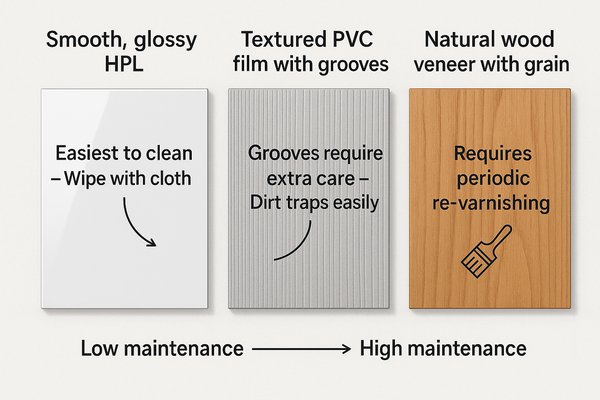

Smooth, non-porous finishes like HPL and high-gloss polyurethane paint are the easiest to clean and maintain. Textured PVC films require more care to clean grooves, and real wood veneers may need periodic re-varnishing to maintain their protective layer and appearance.

Maintenance is a huge factor for ship operators. The ideal surface is one that can be cleaned quickly and effectively with simple, readily available materials. This is why material selection in the design phase is so critical; it has a direct impact on the vessel's operational efficiency for decades to come.

Cleaning and Maintenance Summary

| Finish Type | Recommended Cleaners | Cleaners to AVOID | Long-Term Care |

|---|---|---|---|

| HPL | Mild soap/detergent, warm water, non-abrasive cream cleaners. | Abrasive pads (Scotch-Brite), steel wool, acidic or alkaline cleaners. | None required. |

| PVC/Vinyl Film | Mild soap/detergent, soft sponge, soft-bristle brush for textures. | Harsh solvents (acetone), abrasive cleaners, sharp tools. | Check edges periodically to ensure they are not lifting. |

| Wood Veneer | pH-neutral wood cleaner, a soft, lint-free cloth, damp (not wet) cloth. | Ammonia-based cleaners, all-purpose sprays, excessive water, silicone polish. | May require re-varnishing every 5-10 years depending on wear and UV exposure. |

| Paint/Coatings | Mild detergents, most standard cleaning agents. | Heavy scouring with abrasive pads that can dull the gloss. | Extremely durable. Can be re-coated after many years if needed. |

How Are Scratches, Chips, Or Other Surface Damage Repaired On Different Types Of Panel Finishes?

Worried that accidental damage will ruin your beautiful new panels? Damage is inevitable in a working environment. Knowing how to perform repairs is essential for maintaining the interior's appearance over the long term.

Repairs vary by finish. HPL scratches are filled with color-matched wax kits. Damaged PVC film is repaired by patching, though this can be difficult to blend. Wood veneer damage is fixed with epoxy or wax fillers, followed by sanding and touch-up varnishing.

While reactive repairs are necessary, a proactive approach is even better. In high-traffic corridors, I always recommend installing stainless steel or rubber corner guards. In mess rooms, a "chair rail" can prevent scuffs and dents. These small, upfront investments in protection can save thousands in repair costs and keep the interior looking pristine for much longer.

Surface Repair Methods at a Glance

| Finish Type | Type of Damage | Recommended Repair Method |

|---|---|---|

| HPL | Scratches, chips, gouges. | Use a hard wax repair kit. Melt, mix to match color, fill the damage, and level the surface. |

| PVC/Vinyl Film | Tears, deep scratches. | Patching. Cut out the damaged area and inlay a matching piece of new film. Blending can be difficult. |

| Wood Veneer | Shallow scratches. | Lightly sand the varnish and apply touch-up coats. |

| Wood Veneer | Deeper chips, gouges. | Fill with color-matched putty or epoxy/sawdust mix. Sand smooth, touch up grain/color, and re-varnish. |

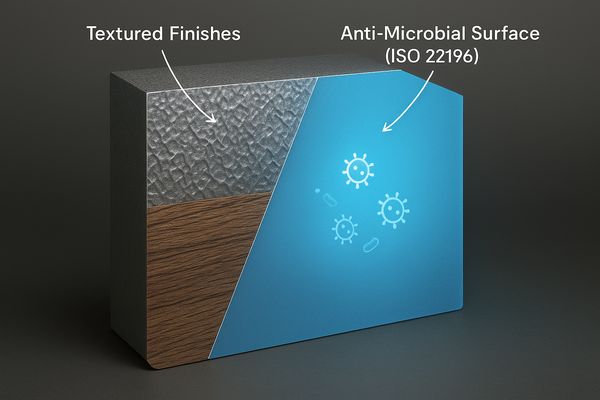

Are There Textured Or Anti-Microbial Surface Finishes Available For Marine Wall Panels?

Looking for a finish with enhanced functionality? Standard smooth surfaces aren't always the best fit, especially for high-design areas or sanitary spaces. You need to know if specialized options are available.

Yes, both textured and anti-microbial surface finishes are widely available. Textured finishes, such as embossed metals or simulated wood grains, add visual depth and durability. Anti-microbial finishes incorporate agents like silver ions, tested under standards like ISO 22196, to inhibit the growth of bacteria, mold, and mildew.

Specialty finishes solve specific problems. Textured metal panels are fantastic for high-abuse areas because the pattern helps to hide fingerprints and minor dents. On the hygiene front, the demand for antimicrobial surfaces has grown significantly. When sourcing these products, I always ask for the test certificate for ISO 221967. This standard provides quantitative proof of the surface's ability to inhibit bacterial growth—a verifiable performance characteristic that adds a crucial layer of safety.

Comparison of Specialized Finishes

| Feature | Textured Finishes | Anti-Microbial Finishes |

|---|---|---|

| Primary Goal | Aesthetic enhancement & improved durability. | Improved hygiene & inhibiting microbe growth. |

| Technology/Examples | Embossed metal patterns (linen, leather), deep-textured HPL and vinyl that mimics wood pores or stone. | Silver ion technology embedded in the finish material (HPL, PVC, paint). |

| Key Benefit | Adds visual interest, hides fingerprints and minor scratches, can increase panel stiffness. | Provides continuous 24/7 protection against bacteria, mold, and mildew. Does not wash off. |

| Best Applications | Feature walls, lobbies, elevators, high-traffic corridors. | Galleys, medical facilities, public restrooms, childcare areas. |

Conclusion

In summary, choosing the right surface finish involves balancing durability, fire safety, aesthetics, and cost. From rugged HPL to versatile PVC films, elegant wood, and protective paints, each has a role in modern marine interiors.

-

Explore this link to understand how HPL enhances durability and aesthetics in shipbuilding applications. ↩

-

Learn how ASTM G154 simulates sunlight exposure to ensure marine finishes resist fading and degradation, crucial for long-lasting performance at sea. ↩

-

Learn how ISO 4586-2 ensures marine finishes withstand heavy use and impacts, crucial for durability in demanding shipboard environments. ↩

-

Learn how ASTM B117 testing ensures materials withstand harsh marine environments, preventing corrosion and extending the lifespan of ship interiors. ↩

-

Exploring this test will provide insights into fire safety standards and how materials are evaluated for flammability. ↩

-

Understanding VOC regulations is crucial for ensuring safe air quality in marine environments. Explore this link for detailed insights. ↩

-

Understanding ISO 22196 is essential for ensuring the safety and effectiveness of antimicrobial surfaces in various applications. ↩